TCT Saw Blade for Slotting

Umbukiso Womkhiqizo

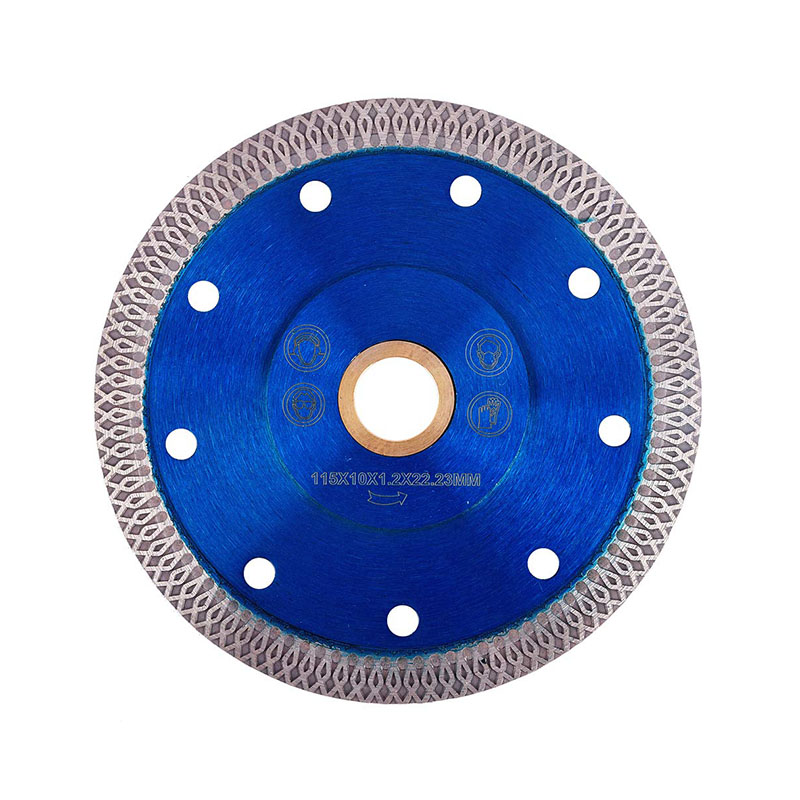

Amazinyo amathathu akule blade yesaha awagcini nje ngokukhulisa amandla ayo okusebenza kodwa futhi angahlangabezana nezidingo eziningi zokusika. Iklanywe ngokucophelela, amazinyo e-blade angahanjiswa kalula kunoma iyiphi indlela. Izohlangabezana nezidingo ezihlukahlukene zokusika futhi ibe nokuhamba okuphezulu. Ngenxa yenani elincane lamazinyo e-blade, imfucumfucu ingasuswa kahle ngesikhathi sokusika, futhi i-blade ngeke ishise ngesikhathi sokusika, ngaleyo ndlela yandise impilo yayo yenkonzo. Ukuklama kwayo kuphinde kuvimbele izingozi nokulimala ngesikhathi sokusika. Lo mklamo uvumela i-saw blade ukuthi igcine ukumelana ne-radial okulungile ngisho nangesivinini esiphezulu, iqinisekisa ukusika okuphephile nokusebenza kahle nokuvimbela i-blade ekushiseni. I-saw blade ayishisi ngesikhathi sokusebenza okuqhubekayo.

Kubalulekile ukukhumbula ukuthi siyakwazi ukusika, ukuma, ukuqeda, nokugaya hhayi kuphela i-plywood, i-particle board, i-laminate, i-drywall, ipulasitiki, i-hardboard ye-MDF, i-chipboard, i-laminate flooring, i-plasterboard, i-parquet, i-plastic kanye ne-hardboard ye-MDF, kodwa singenza okufanayo nge-plywood, i-particleboard, i-laminate, i-plasterboard, i-parquet, i-plastic kanye ne-MDF hardboard. Izinyo le-plywood lidinga ukulolongwa futhi lihlanzwe ngendlela eqinisekisa ukuthi imiphumela emihle iyatholakala.

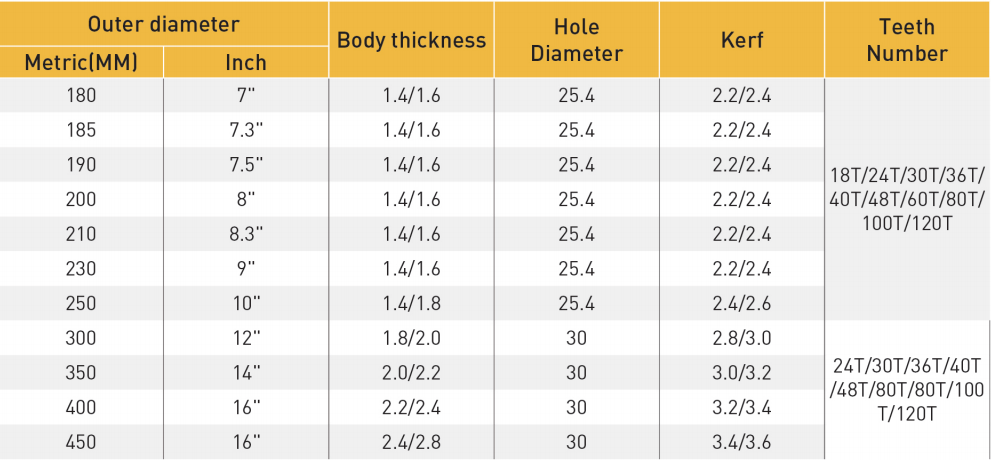

Usayizi Womkhiqizo