Yini iziTwist Drills?

I-Twist drill yitemu elijwayelekile lezinhlobo ezahlukene zokubhoboza, ezifana nokubhola kwensimbi, ukubhola kwepulasitiki, ukubhola ngokhuni, ukubhola kwendawo yonke, ukwakhiwa kwamatshe kanye nokubhola kukakhonkolo. Wonke ama-twist drill anesici esifanayo: Imitshingo ye-helical enikeza ama-drill igama lawo. Ama-twist drill ahlukene asetshenziswa kuye ngobulukhuni bento ezokwenziwa ngomshini.

Nge-engeli ye-helix

Uhlobo N

●Ifanele izinto ezijwayelekile ezifana nensimbi ekhonjiwe.

●Uhlobo lwe-N cutting wedge luguquguquka ngenxa ye-engeli yalo yokusonta ye-approx. 30°.

I-engeli yephoyinti yalolu hlobo ngu-118 °.

Uhlobo H

●Ilungele izinto eziqinile neziphukayo njengethusi.

●I-engeli ye-helix yohlobo H icishe ibe ngu-15°, okuholela ku-engeli enkulu ye-wedge enomkhawulo wokusika obukhali kancane kodwa ozinze kakhulu.

●Ukubhola kohlobo H nakho kune-engeli yephoyinti engu-118°.

Uhlobo W

●Isetshenziselwa izinto ezithambile ezifana ne-aluminium.

●I-engeli ye-helix ye-approx. U-40° uphumela ku-engeli encane ye-wedge yokusika okubukhali kodwa okungazinzile uma kuqhathaniswa.

●I-engeli yephoyinti ingu-130°.

Ngezinto ezibonakalayo

I-High Speed Steel (HSS)

Izinto ezisetshenziswayo zingahlukaniswa cishe zibe izinhlobo ezintathu: insimbi enesivinini esikhulu, insimbi enesivinini esikhulu i-cobalt ne-carbide eqinile.

Kusukela ngo-1910, insimbi enesivinini esiphezulu isetshenziswe njengethuluzi lokusika iminyaka engaphezu kwekhulu. Njengamanje iyona nto esetshenziswa kakhulu futhi eshibhe kakhulu yamathuluzi okusika. Izinsimbi zensimbi ezinesivinini esikhulu zingasetshenziswa kuzo zombili izimbobo zezandla kanye nemvelo ezinzile njengomshini wokubhoboza. Esinye isizathu sokuthi kungani insimbi enesivinini esiphezulu ihlala isikhathi eside kungase kube ukuthi amathuluzi okusika insimbi anesivinini esiphezulu angaphinde afakwe phansi. Ngenxa yentengo ephansi, ayisetshenziswanga kuphela ukugaya ama-drillbits, kodwa futhi isetshenziswa kabanzi ekuphenduleni amathuluzi.

I-Cobalt-Containing High-Speed Steel (HSSE)

Insimbi enesivinini esiphezulu equkethe i-cobalt inobulukhuni obungcono nobulukhuni obubomvu kunensimbi enesivinini esikhulu. Ukwanda kobulukhuni nakho kuthuthukisa ukumelana kwayo kokugqoka, kodwa ngesikhathi esifanayo kudela ingxenye yokuqina kwayo. Okufanayo nensimbi enesivinini esikhulu: zingasetshenziswa ukwandisa inani lezikhathi ngokugaya.

I-Carbide (CARBIDE)

I-Cementcarbide iyinhlanganisela yezinto ezenziwe ngensimbi. Phakathi kwazo, i-tungsten carbide isetshenziswa njenge-matrix, kanti ezinye izinto ezisetshenziswayo zisetshenziswa njengezibophezelo zokufaka i-sinter ngokucindezela okushisayo kwe-isostatic kanye nochungechunge lwezinqubo eziyinkimbinkimbi. Uma kuqhathaniswa nensimbi enesivinini esikhulu mayelana nobunzima, ubulukhuni obomvu nokumelana nokugqoka, kuye kwaba ngcono kakhulu. Kodwa izindleko zamathuluzi okusika i-carbide enosimende nazo zibiza kakhulu kunensimbi enesivinini esikhulu. I-carbide enosimende inezinzuzo eziningi kunezinto zamathuluzi zangaphambilini ngokwempilo yamathuluzi nesivinini sokucubungula. Ekugayweni okuphindaphindiwe kwamathuluzi, amathuluzi okugaya adingekayo ayadingeka.

Ngokugcoba

Kungagqotshiwe

Ama-coatings angahlukaniswa cishe abe yizinhlobo ezinhlanu ezilandelayo ngokuya kobubanzi bokusetshenziswa:

Amathuluzi angamboziwe ashibhile futhi avamise ukusetshenziselwa ukucubungula izinto ezithambile ezifana ne-aluminium alloy ne-low carbon steel.

I-Black oxide Coating

Izembatho ze-oksidi zinganikeza ukuthambisa okungcono kunamathuluzi angamboziwe, futhi zingcono ekuphikisweni kwe-oxidation nokumelana nokushisa, futhi zingandisa impilo yesevisi ngaphezu kuka-50%.

I-Titanium Nitride Coating

I-Titanium nitride iyinto ejwayeleke kakhulu yokuhlanganisa, futhi ayifanele izinto ezinobunzima obuphezulu kanye nezinga lokushisa eliphezulu lokucubungula.

I-Titanium Carbonitride Coating

I-Titanium carbonitride ithuthukiswa isuka ku-titanium nitride, inokumelana nezinga lokushisa eliphakeme nokumelana nokugqoka, ngokuvamile okunsomi noma okuluhlaza okwesibhakabhaka. Isetshenziswa endaweni yokusebenzela yakwa-Haas umshini wokwenza izinto ezenziwe ngensimbi ecijile.

I-Titanium Aluminium Nitride Coating

I-Titanium aluminium nitride imelana kakhulu namazinga okushisa aphezulu kunazo zonke izimbotshana ezingenhla, ngakho-ke ingasetshenziswa ezindaweni zokusika eziphakeme. Ngokwesibonelo, ukucubungula superalloys. Ibuye ifanele ukucutshungulwa kwensimbi nensimbi engagqwali, kodwa ngenxa yokuthi iqukethe izakhi ze-aluminium, ukusabela kwamakhemikhali kuzokwenzeka lapho kucutshungulwa i-aluminium, ngakho gwema ukucubungula izinto eziqukethe i-aluminium.

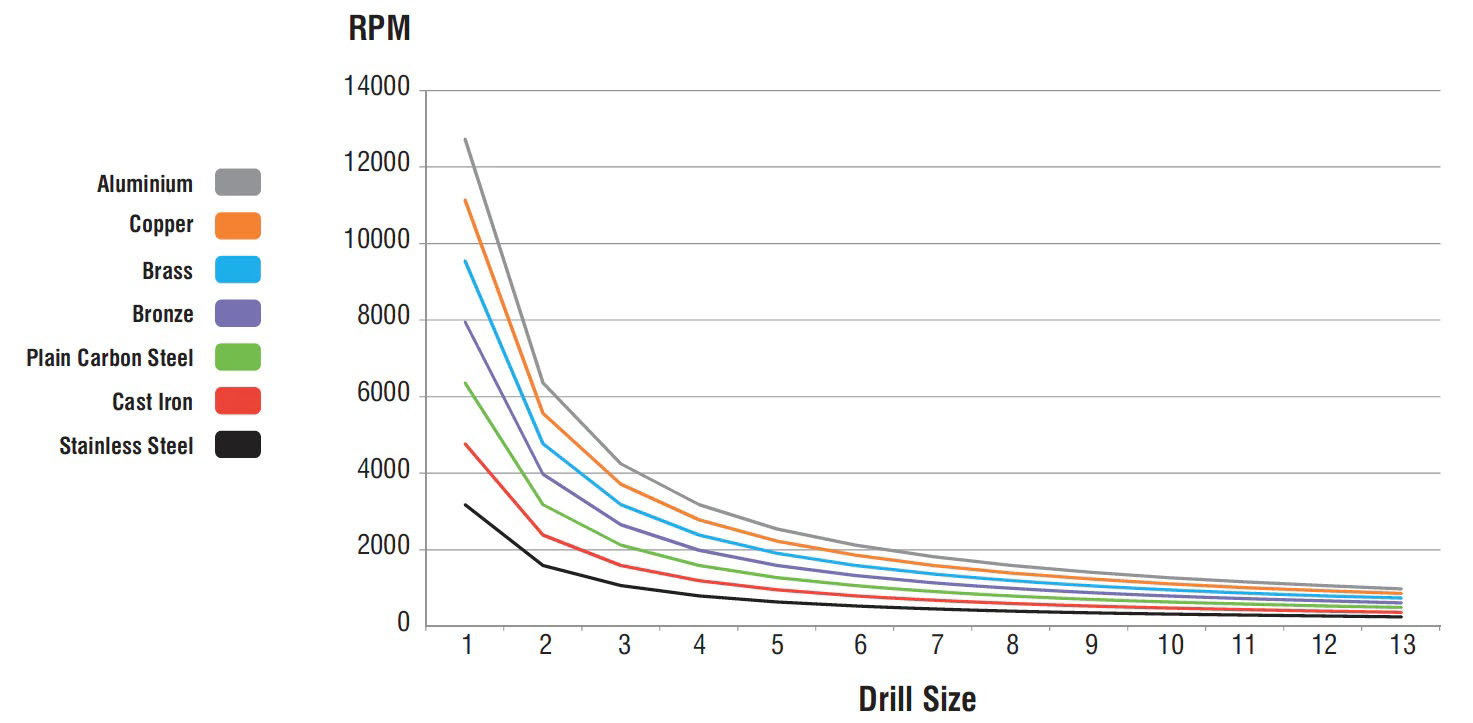

Isivinini Sokubhoboza Esinconyiwe Ngensimbi

| Usayizi Wokubhoboza | |||||||||||||

| 1MM | 2MM | 3MM | 4MM | 5MM | 6MM | 7MM | 8MM | 9MM | 10MM | 11MM | 12MM | 13MM | |

| OKUNGANINIIZINSIMBI | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| INSIMBI | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| I-PLAINIKHABONIIZINSIMBI | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 | 795 | 707 | 636 | 579 | 530 | 490 |

| ITHUSI | 7955 | 3977 | 2652 | 1989 | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| ITHUSI | 9545 | 4773 | 3182 | 2386 | 1909 | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| ITHUPHA | 11136 | 5568 | 3712 | 2784 | 2227 | 1856 | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| ALUMINIUM | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818 | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Yiziphi izivivinyo ze-HSS?

Izinsimbi ze-HSS ziyizinsimbi zensimbi ezibonakala ngamathuba azo okusebenza kwendawo yonke. Ikakhulukazi ekukhiqizweni kochungechunge oluncane nolumaphakathi, ezimeni zemishini ezingazinzile nanoma nini uma kudingeka ukuqina, abasebenzisi basathembela kumathuluzi okumba ensimbi enesivinini esikhulu (HSS/HSCO).

Umehluko ku-HSS drill

Insimbi enesivinini esikhulu ihlukaniswe ngamaleveli ekhwalithi ahlukene kuye ngobulukhuni nokuqina. Izingxenye ze-alloy ezifana ne-tungsten, i-molybdenum ne-cobalt zinesibopho salezi zakhiwo. Ukwenyuka kwezingxenye ze-alloy kukhulisa ukumelana nokushisa, ukumelana nokugqoka nokusebenza kwethuluzi, kanye nenani lokuthenga. Yingakho kubalulekile ukucabangela ukuthi zingaki izimbobo okufanele zenziwe kuzo izinto ezibonakalayo lapho ukhetha izinto zokusika. Ngenani elincane lezimbobo, kunconywa into yokusika engabizi kakhulu i-HSS. Izinto zokusika ezisezingeni eliphakeme njenge-HSCO, M42 noma i-HSS-E-PM kufanele zikhethelwe ukukhiqizwa kochungechunge.

| Ibanga le-HSS | HSS | I-HSCO(futhi i-HSS-E) | M42(kanye ne-HSCO8) | PM HSS-E |

| Incazelo | Insimbi evamile enesivinini esikhulu | I-Cobalt alloyed high speed steel | 8% cobalt alloyed high speed steel | I-powder metallurgically ekhiqizwa insimbi enesivinini esikhulu |

| Ukwakheka | Ubukhulu. 4.5% cobalt kanye 2.6% vanadium | Okuncane. 4.5% cobalt noma 2.6% vanadium | Okuncane. 8% i-cobalt | Izithako ezifanayo njenge-HSCO, ukukhiqizwa okuhlukile |

| Sebenzisa | Ukusetshenziswa kwendawo yonke | Sebenzisa izinga lokushisa eliphezulu lokusika/ukupholisa okungekuhle, insimbi engagqwali | Sebenzisa ngezinto okunzima ukuzisika | Sebenzisa ekukhiqizeni uchungechunge kanye nezidingo zempilo yamathuluzi aphezulu |

Ishadi Lokukhetha Ibhithi le-HSS Drill

| AMAPLASTIKI | ALUMINIUM | ITHUPHA | ITHUSI | ITHUSI | I-PLAIN CARBON STEEL | INSIMBI | INSIMBI ENGAGQWALI | ||||

| IZINHLOSO EZININGI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| I-INDUSTRIAL METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| IMETALI EZINGA | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| I-TITANIUM ehlanganisiwe | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| I-TURBO METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSngeI-COBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Ishadi Lokukhetha Ibhithi Ye-Masonry Drill

| ISITINA SOBUMBA | ISITINA SOMLILO | B35 OKWENELE | B45 OKWENELE | UKHONSI OQINISELWE | IGRANITE | |

| OkujwayelekileIZItini | ✔ | ✔ | ||||

| Ukhonkolo Wezimboni | ✔ | ✔ | ✔ | |||

| I-TURBO CONCRETE | ✔ | ✔ | ✔ | ✔ | ||

| Izinga le-SDS | ✔ | ✔ | ✔ | |||

| I-SDS INDUSTRIAL | ✔ | ✔ | ✔ | ✔ | ||

| SDS PROFESSIONAL | ✔ | ✔ | ✔ | ✔ | ✔ | |

| I-SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| I-SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| IZINHLOSO EZININGI | ✔ |

|

|

|

|