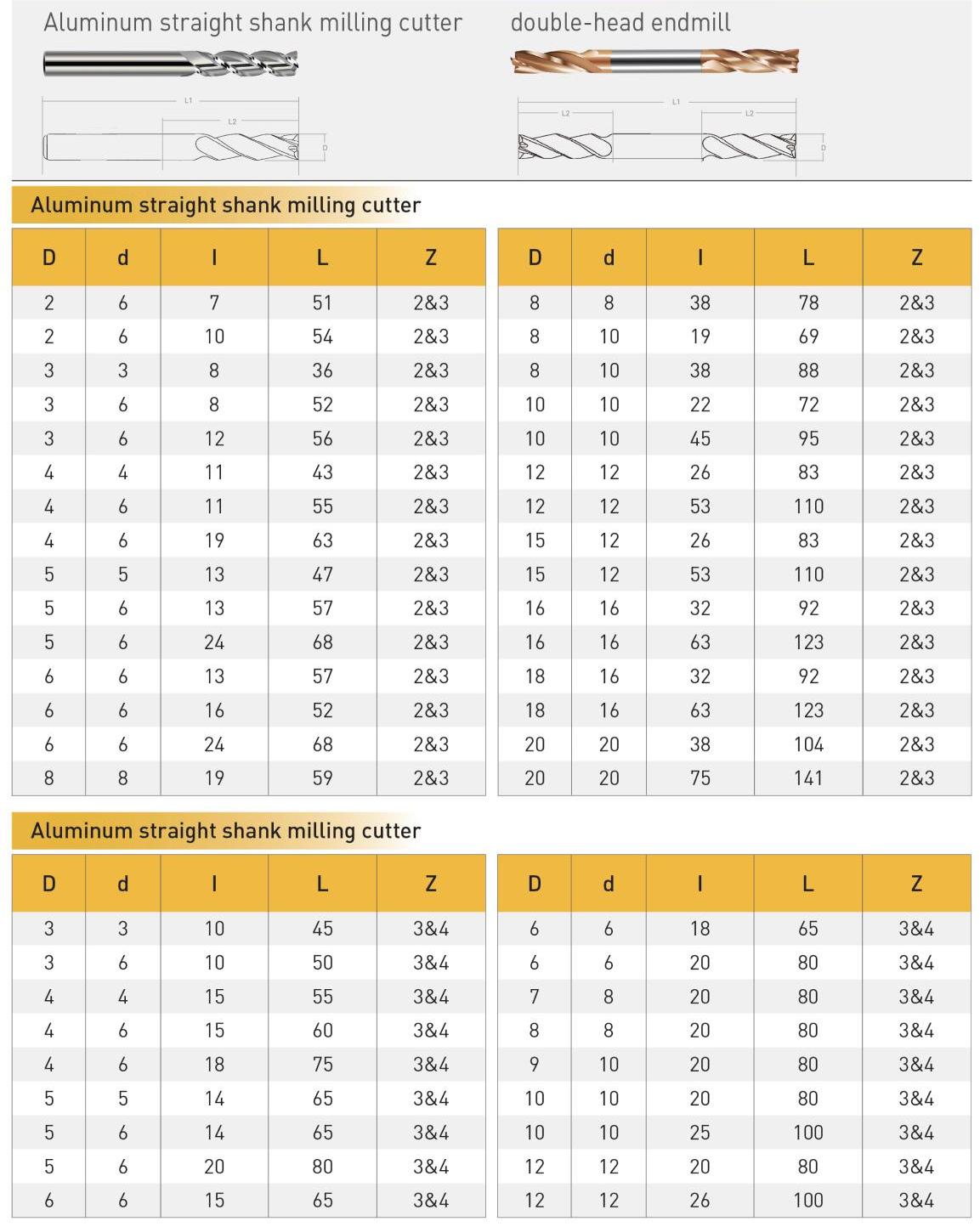

I-Aluminium Straight Shank Milling Cutter

Usayizi Womkhiqizo

Incazelo Yomkhiqizo

Ukumelana nokushisa kwama-milling cutters nakho kungenye yezindawo zayo ezibalulekile. Phakathi nenqubo yokusika, ithuluzi likhiqiza inani elikhulu lokushisa, ikakhulukazi lapho isivinini sokusika siphezulu, izinga lokushisa lizokhuphuka kakhulu. Uma ukumelana nokushisa kwethuluzi kungalungile, kuzolahlekelwa ubulukhuni bayo emazingeni okushisa aphezulu, okuholela ekunciphiseni kokusika ukusebenza kahle. Izinto zethu zokusika izigayo zinokumelana nokushisa okuhle kakhulu, okusho ukuthi zigcina ubulukhuni obuphezulu emazingeni okushisa aphezulu, okuzivumela ukuthi ziqhubeke nokusika. Le mpahla yobulukhuni bezinga eliphezulu lokushisa ibizwa nangokuthi i-thermohardness noma ukuqina okubomvu. Kuphela ngokumelana nokushisa okuhle ithuluzi lokusika lingakwazi ukugcina ukusebenza okuzinzile kokusika ngaphansi kwezimo zokushisa eziphezulu futhi kugweme ukwehluleka kwamathuluzi ngenxa yokushisa.

Ngaphezu kwalokho, abasiki be-erurocut milling nabo banamandla aphezulu kanye nokuqina okuhle. Phakathi nenqubo yokusika, ithuluzi lokusika lidinga ukumelana namandla amakhulu omthelela, ngakho-ke kufanele libe namandla aphezulu, ngaphandle kwalokho lizophuka kalula futhi lonakaliswe. Ngesikhathi esifanayo, ngenxa yokuthi abasiki bokugaya bazothinteka futhi badlidlize phakathi nenqubo yokusika, kufanele futhi babe nokuqina okuhle ukuze bagweme izinkinga ezinjengokuqoshwa nokusika. Kuphela ngalezi zakhiwo ithuluzi lokusika lingakwazi ukugcina amandla okusika azinzile futhi anokwethenjelwa ngaphansi kwezimo zokusika eziyinkimbinkimbi nezishintshayo.

Lapho ufaka futhi ulungisa i-milling cutter, izinyathelo zokusebenza eziqinile kufanele zithathwe ukuze kuqinisekiswe ukuthintana okulungile kanye ne-engeli yokusika phakathi kwe-milling cutter kanye ne-workpiece. Lokhu akusizi nje ukuthuthukisa ukusebenza kahle kokucubungula, kodwa futhi kugwema ukulimala kwengcezu yokusebenza noma ukwehluleka kwemishini okubangelwa ukulungiswa okungalungile.