Ivili lokuSila iTurbo yezinyo elibanzi

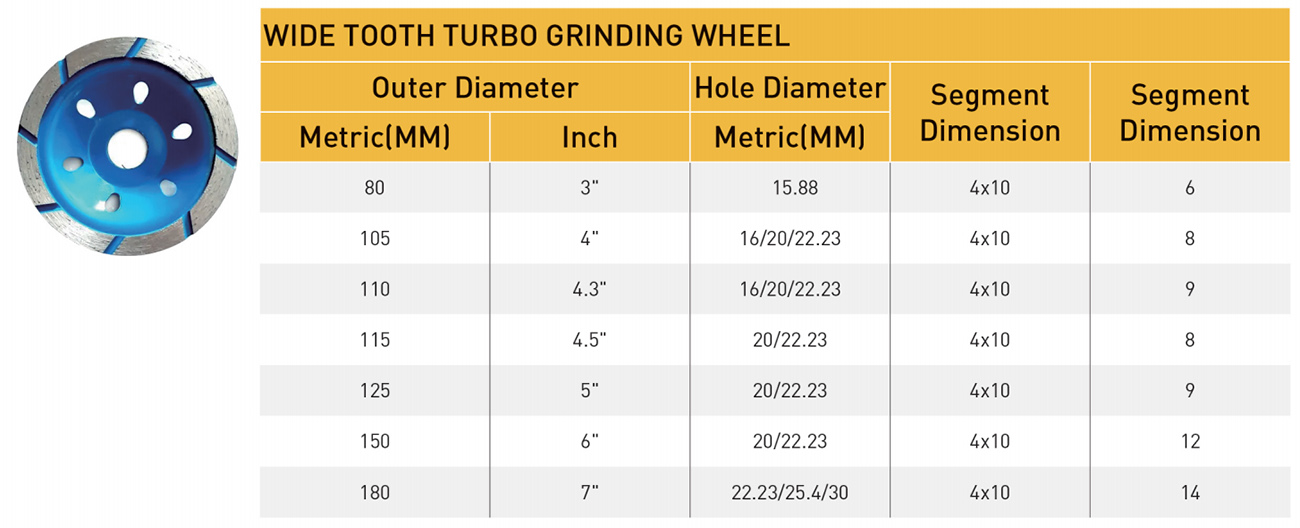

Ubungakanani bemveliso

Ingcaciso yeMveliso

Phakathi kwezizathu ezininzi zedayimani zixatyiswe kakhulu kukunganyangeki kwazo kunye nokuqina kwazo. Iidayimani zineenkozo ezibukhali ezinokungena lula kwizinto zokusebenza. Ngenxa ye-thermal conductivity ye-diamonds, ukushisa okwenziwa ngexesha lokusika kudluliselwa ngokukhawuleza kwi-workpiece, okubangela ukushisa okuphantsi kokugaya. Amavili ekomityi yedayimani anemiphetho ebanzi kunye ne-corrugations ilungele ukupakisha imiphetho erhabaxa ukuze igudiswe, kuba ivumela umphezulu wonxibelelwano ukuba ulungelelanise ngokulula kwaye ngokukhawuleza kwiimeko ezahlukeneyo, okukhokelela ekugqityweni okugudileyo. Iingcebiso zedayimani zidluliselwa kumavili okugaya nge-high-frequency welding, eqinisekisa ukuba zihlala zizinzile kwaye zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala ixesha elide. Ngokwenza njalo, zonke iinkcukacha zinokuphathwa ngokufanelekileyo nangenkathalo enkulu. Ibhalansi eguqukayo kunye novavanyo lwenziwa kwivili ngalinye lokusila ukuze kufumaneke amavili okusila aphuculweyo.

Kubalulekile ukukhetha i-diamond saw blade ebukhali kwaye ihlala ixesha elide ukwenzela ukuba isetyenziswe iminyaka emininzi. I-Diamond saw blades zenzelwe ukubonelela ngemveliso yomgangatho ophezulu oya kuhlala ixesha elide. Ngamava ethu ekuveliseni amavili okusila, sikunika iindidi ezininzi zeemveliso ezikwazi ukugaya ngesantya esiphezulu, kunye neendawo ezinkulu zokusila, kunye nokusebenza kakuhle kokugaya.