Zintoni iiTwist Drills?

I-Twist drill ligama eliqhelekileyo kwiindidi ezahlukeneyo zoqheliso, ezifana nokubhola kwentsimbi, ukubhola kweplastiki, uqheliso lwamaplanga, uqheliso lwehlabathi lonke, ukwakhiwa kweemasonry kunye nokukrola ikhonkrithi. Zonke ii-twist drills zinempawu ezifanayo: Iifleyiti ze-helical ezinika iidrill igama labo. Ii-twist drills ezahlukeneyo zisetyenziswa ngokuxhomekeke kubunzima bezinto eziza kwenziwa ngoomatshini.

Ngeengile ye-helix

Uhlobo N

●Ifanelekile kwizinto eziqhelekileyo ezifana nentsimbi.

●Uhlobo lwe-N yokusika i-wedge iyaguquguquka ngenxa ye-engile yayo ye-twist ye-approx. 30 °.

I-angle yenqaku yolu hlobo yi-118 °.

Uhlobo H

●Ilungele izinto ezilukhuni kunye ne-brittle ezifana ne-bronze.

●Uhlobo lwe-H i-angle ye-helix ijikeleze i-15 °, okukhokelela kwi-angle ye-wedge enkulu kunye ne-edge yokusika ebukhali kodwa ezinzile kakhulu.

●Ii-drill zodidi lwe-H nazo zine-angle ye-118 °.

Uhlobo W

●Isetyenziselwa izinto ezithambileyo ezifana nealuminium.

●I-engile ye-helix ye-approx. I-40 ° ibangela i-engile encinci ye-wedge ye-edge ebukhali kodwa engazinzanga ngokuthelekisayo.

●I-engile yenqaku yi-130 °.

Ngezinto eziphathekayo

Intsimbi yesantya esiphezulu (HSS)

Izinto eziphathekayo zinokwahlulwa ngokufanelekileyo zibe ziindidi ezintathu: isinyithi esinesantya esiphezulu, i-cobalt equkethe i-high-speed steel kunye ne-carbide eqinile.

Ukususela ngo-1910, isinyithi esinesantya esiphezulu sisetyenziswe njengesixhobo sokusika iminyaka engaphezu kwekhulu. Okwangoku yeyona nto isetyenziswa kakhulu kwaye inexabiso eliphantsi kwizixhobo zokusika. I-Speed-speed drills inokusetyenziswa kwi-drill yezandla zombini kunye nokusingqongileyo okuzinzileyo okufana nomatshini wokugaya. Esinye isizathu sokuba isinyithi esinesantya esiphezulu sihlala ixesha elide sinokuba ngenxa yokuba izixhobo zokusika isinyithi esinesantya esiphezulu zinokubuyiselwa ngokuphindaphindiweyo. Ngenxa yexabiso layo eliphantsi, ayisetyenziswanga kuphela ukugaya i-drillbits, kodwa isetyenziswa ngokubanzi ekujikeni izixhobo.

I-Cobalt equlathe iNtsimbi yesantya esiphezulu (HSSE)

I-Cobalt-equkethe i-high-speed steel inobunzima obungcono kunye nobunzima obomvu kunentsimbi ephezulu. Ukunyuka kobunzima kukwaphucula ukuxhathisa kwayo, kodwa kwangaxeshanye kuncama inxalenye yokuqina kwayo. Kuyafana nentsimbi yesantya esiphezulu: zingasetyenziselwa ukwandisa inani lamaxesha ngokugaya.

ICarbide (CARBIDE)

I-Cementcarbide yimathiriyeli edibeneyo esekelwe kwisinyithi. Phakathi kwazo, i-tungsten carbide isetyenziswa njenge-matrix, kwaye ezinye izinto zisetyenziswa njengezibophelelo zokutshiza ngokucinezela kwe-isostatic kunye nothotho lweenkqubo ezinzima. Xa kuthelekiswa nentsimbi yesantya esiphezulu ngokubhekiselele kobunzima, ubunzima obomvu kunye nokuxhatshazwa kokugqoka, kuye kwaphuculwa kakhulu. Kodwa iindleko zezixhobo zokusika i-carbide zixabisa kakhulu kunentsimbi ephezulu. I-carbide ene-cemented ineenzuzo ezininzi kunezixhobo zangaphambili zesixhobo ngokubhekiselele kubomi besixhobo kunye nesantya sokucubungula. Ekusileni ngokuphindaphindiweyo izixhobo, izixhobo zokugaya iingcali zifunekayo.

Ngokugquma

Ingagqunywanga

Iingubo zinokwahlulwa ngokwezi ntlobo zintlanu zilandelayo ngokobubanzi bokusetyenziswa:

Izixhobo ezingagqunywanga zezona zinexabiso eliphantsi kwaye zidla ngokusetyenziselwa ukusetyenzwa kwemathiriyeli ethambileyo efana ne-aluminium alloy kunye nentsimbi ephantsi yekhabhoni.

I-Black oxide Coating

Iingubo ze-oxide zinokubonelela nge-lubricity engcono kunezixhobo ezingagqunywanga, zikwangcono kwi-oxidation kunye nokumelana nobushushu, kwaye zinokunyusa ubomi benkonzo ngaphezu kwe-50%.

I-Titanium Nitride Coating

I-Titanium nitride yeyona nto ixhaphakileyo yokugquma, kwaye ayifanelekanga kwizinto ezinobulukhuni obuphezulu kunye nobushushu obuphezulu.

I-Titanium Carbonitride Coating

I-Titanium carbonitride iphuhliswa kwi-titanium nitride, inokumelana nobushushu obuphezulu kunye nokumelana nokunxiba, ngokuqhelekileyo imfusa okanye eluhlaza okwesibhakabhaka. Isetyenziswe kwiworkshop ye-Haas kumatshini wokusebenzela owenziwe ngentsimbi.

I-Titanium Aluminiyam yeNitride yoMgquba

I-Titanium aluminium nitride ixhathisa kakhulu kumaqondo okushisa aphezulu kunazo zonke iingubo ezingentla, ngoko ingasetyenziselwa kwiindawo eziphezulu zokusika. Umzekelo, ukusetyenzwa kwe-superalloys. Ikwafanelekile ukucutshungulwa kwentsimbi kunye nensimbi engenasici, kodwa ngenxa yokuba iqulethe izinto ze-aluminium, ukuphendulwa kweekhemikhali kuya kwenzeka xa kusetyenzwa i-aluminium, ngoko ugweme izinto zokucubungula ezine-aluminium.

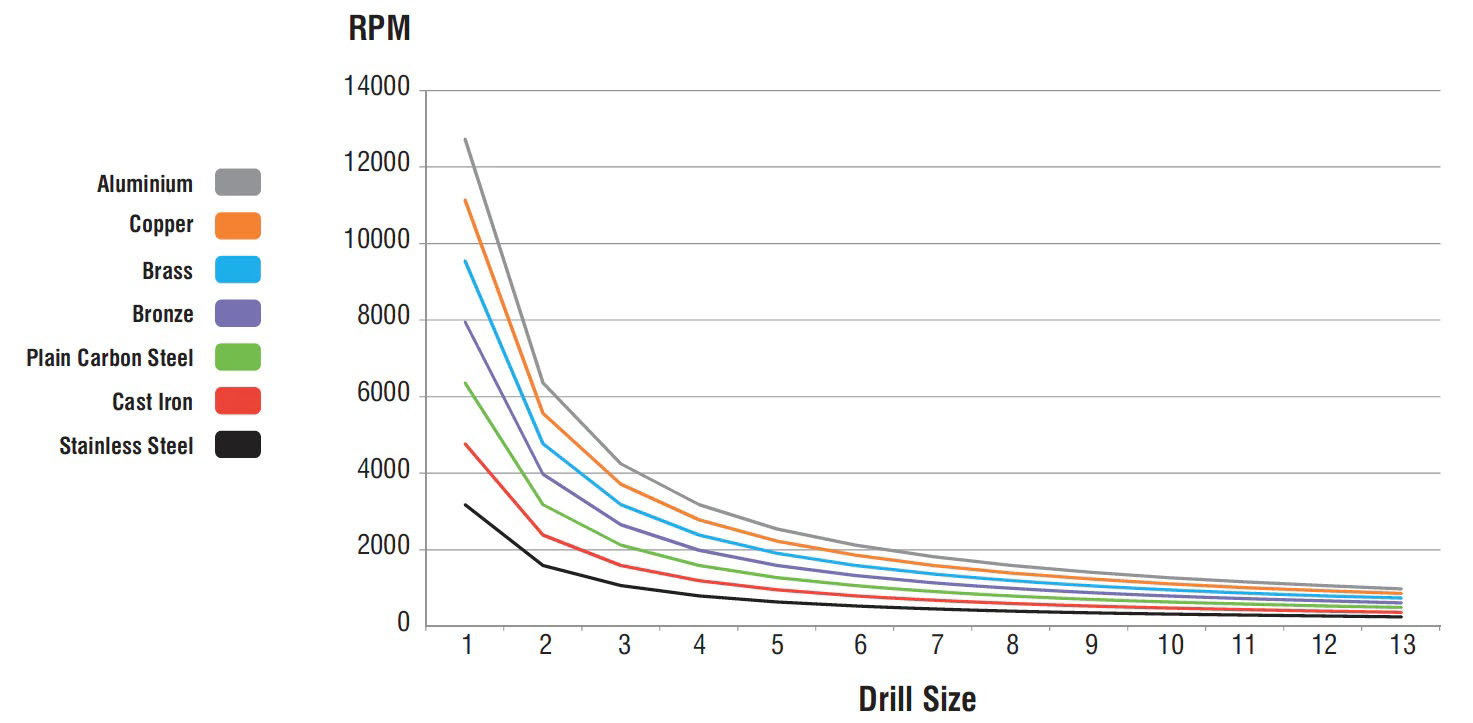

Izantya zokuBomba ezicetyiswayo kwiMetal

| Ubungakanani beDrill | |||||||||||||

| 1MM | 2MM | 3MM | 4MM | 5MM | 6MM | 7MM | 8MM | 9MM | 10MM | 11MM | 12MM | 13MM | |

| AYINAKUBIIntsimbi | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| JULA I-AYINI | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| I-PLAINIkhabhoniIntsimbi | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 | 795 | 707 | 636 | 579 | 530 | 490 |

| IBRONZE | 7955 | 3977 | 2652 | 1989 | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| UBHESI | 9545 | 4773 | 3182 | 2386 | 1909 | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| UKWEPHA | 11136 | 5568 | 3712 | 2784 | 2227 | 1856 | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| ALUMINIM | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818 | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Zeziphi ii-HSS drills?

I-HSS drills zintsimbi zentsimbi ezibonakaliswa ngamathuba azo okusebenza jikelele. Ngokukodwa kwimveliso yochungechunge oluncinci kunye oluphakathi, kwiimeko zokungazinzi kunye nanini na ubunzima bufunekayo, abasebenzisi basathembela kwi-speed-speed steel (HSS / HSCO) izixhobo zokugaya.

Umahluko kwi-HSS drills

Intsimbi yesantya esiphezulu ihlukaniswe ngamanqanaba ahlukeneyo omgangatho ngokuxhomekeke kubunzima kunye nokuqina. Izixhobo ze-alloy ezifana ne-tungsten, i-molybdenum kunye ne-cobalt zijongene nezi zakhiwo. Ukwandisa amacandelo e-alloy kwandisa ukunyanzeliswa kwe-temperature, ukumelana nokunxiba kunye nokusebenza kwesixhobo, kunye nexabiso lokuthenga. Yingakho kubalulekile ukuqwalasela ukuba zingaphi izimbobo eziza kwenziwa kwizinto eziphathekayo xa ukhetha izinto zokusika. Kwinani elincinci lemingxuma, eyona nto ixabisa kakhulu i-HSS yokusika iyanconywa. Izinto zokusika ezikumgangatho ophezulu ezifana ne-HSCO, i-M42 okanye i-HSS-E-PM kufuneka zikhethwe kwimveliso yochungechunge.

| Ibakala leHSS | HSS | HSCO(kunye ne-HSS-E) | M42(kunye ne-HSCO8) | PM HSS-E |

| Inkcazo | Intsimbi eqhelekileyo enesantya esiphezulu | Cobalt alloyed ngesantya esiphezulu intsimbi | I-8% ye-cobalt edibeneyo yentsimbi yesantya esiphezulu | I-powder metallurgically eveliswa ngentsimbi ephezulu |

| Ukuqamba | Max. I-4.5% ye-cobalt kunye ne-2.6% ye-vanadium | Min. I-4.5% ye-cobalt okanye i-2.6% ye-vanadium | Min. I-8% ye-cobalt | Izithako ezifanayo njenge-HSCO, imveliso eyahlukileyo |

| Sebenzisa | Ukusetyenziswa ngokubanzi | Sebenzisa amaqondo okushisa aphezulu / ukupholisa okungathandekiyo, insimbi engenasici | Sebenzisa ngezinto ezinzima-ukusika | Ukusetyenziswa kwimveliso yochungechunge kunye neemfuno eziphezulu zobomi besixhobo |

Itshathi yokuKhetha iBit yeHSS Drill

| IIplastiki | ALUMINIM | UKWEPHA | UBHESI | IBRONZE | INKCAZELO YEKHARBONI YEPLAIN | JULA I-AYINI | YENZIWE NGENTSIMBI ESHAYINAYO | ||||

| IINJONGO EZININZI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| IMETALI YOMZIMBA | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| UMGANGATHO WEMETALI | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| TITANIUM iqatywe | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| I-TURBO METALI | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSngeI-COBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Itshathi yokuKhetha iBit yeMasonry Drill

| IZITENYA ZOBUDONGA | IZITETA ZOMLILO | B35 ENKONLE | B45 ENKONLE | I-Concrete eQINISEKILEYO | GRANITE | |

| UmgangathoIZITENYA | ✔ | ✔ | ||||

| I-Concrete yoShishino | ✔ | ✔ | ✔ | |||

| TURBO CONCRETE | ✔ | ✔ | ✔ | ✔ | ||

| UMGANGATHO WE-SDS | ✔ | ✔ | ✔ | |||

| SDS INDUSTRIAL | ✔ | ✔ | ✔ | ✔ | ||

| SDS PROFESSIONAL | ✔ | ✔ | ✔ | ✔ | ✔ | |

| I-SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| IINJONGO EZININZI | ✔ |

|

|

|

|