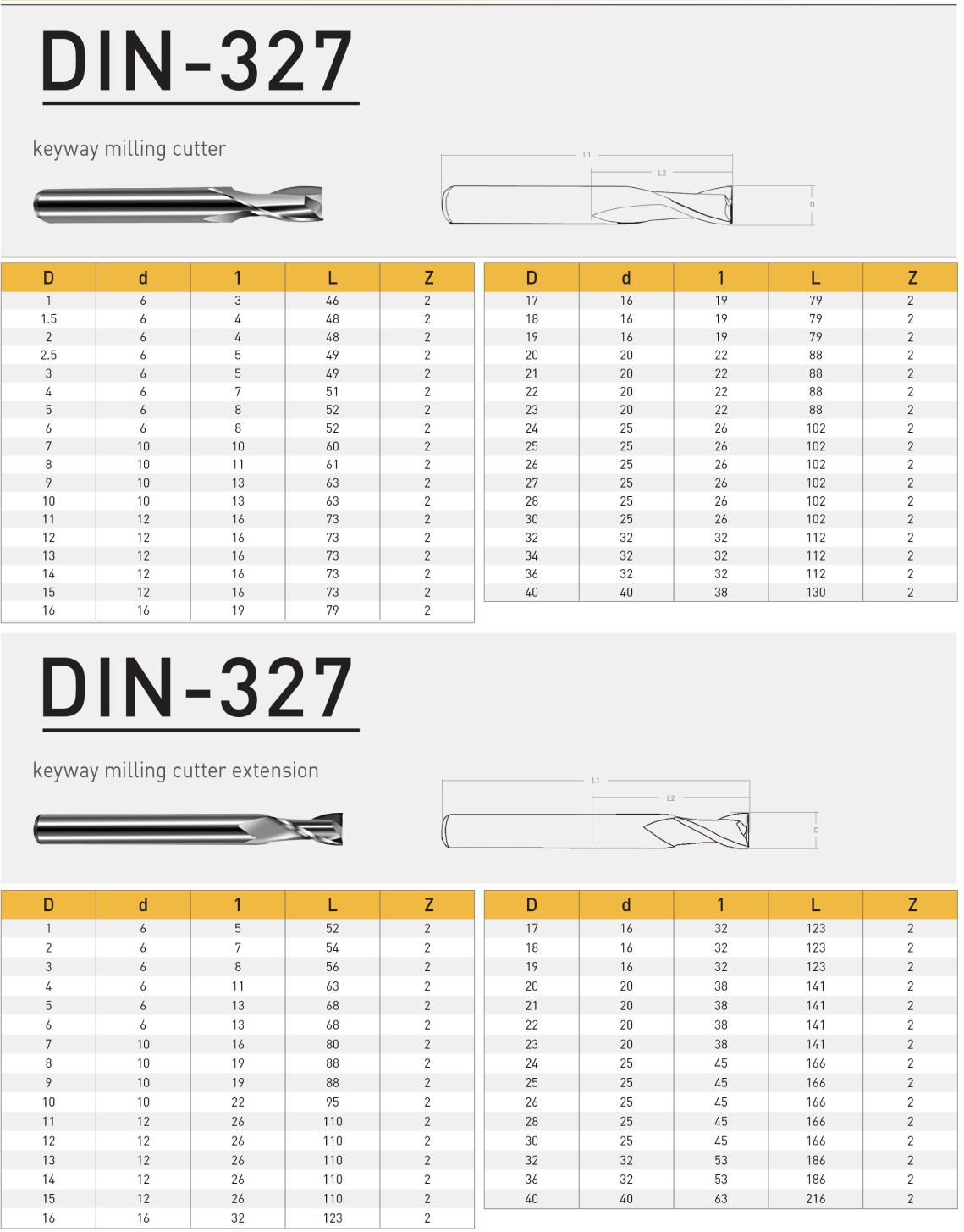

DIN327 Standard End Mill Cutter

Ubungakanani bemveliso

Ingcaciso yeMveliso

Ngezantya zokusika eziphezulu, ukusika kuvelisa ubushushu obuninzi, nto leyo ebangela ukuba amaqondo obushushu anyuke ngokukhawuleza ngenxa yoko. Ukungabikho kokumelana nokushisa okulungileyo, isixhobo siya kulahlekelwa ubunzima baso kumaqondo aphezulu okushisa, ukunciphisa ukusebenza kwayo kokusika. Izinto zethu zokusika i-milling zihlala ziqinile nakwiqondo lokushisa eliphezulu, zivumela ukuba ziqhubeke nokusika ngaphandle kwamaqondo obushushu aphezulu. Le propati ikwabizwa ngokuba yi-thermohardness okanye ubulukhuni obubomvu. Ukuthintela ukufudumala ukusuka ekukhokelela ekungaphumeleli kwesixhobo phantsi kokushisa okuphezulu kunye nokugcina ukusebenza okuzinzile kokusika, izixhobo zokusika ezichasene nobushushu ziyafuneka.

Ngethuba lenkqubo yokusika, abasiki be-cutter kufuneka bakwazi ukujamelana nempembelelo eninzi, ngaphandle koko baya kuphuka ngokulula. I-Erurocut milling cutters ayinamandla kwaye inzima kuphela, kodwa inzima. Kuba umsiki wokusila uya kuchaphazeleka kwaye angcangcazele ngexesha lenkqubo yokusika, kufuneka kube nzima ukunqanda iingxaki zokutshiphuna kunye netshiphu. Kuphela kuxa izixhobo zokusika zinezi mpawu apho ziya kuthi zikwazi ukusebenza ngokungaguqukiyo nangokuthembeka phantsi kweemeko eziguqukayo nezintsonkothileyo zokusika.

Ufakelo kunye nokulungelelaniswa kwe-cutter yokugaya kufuneka kulandelwe iinkqubo zokusebenza ezingqongqo zokuqinisekisa ukuba i-cutter idibene kwaye i-angled ngokuchanekileyo kunye ne-workpiece. Ngokwenza njalo, siya kukwazi ukuphucula ukusebenza kakuhle kunye nokuthintela ukungaphumeleli kwezixhobo kunye nomonakalo womsebenzi ngenxa yokulungelelaniswa okungafanelekanga.