I-BS122 iMgangatho weSibini iSithathu seFlute eSine sokuPhelisa

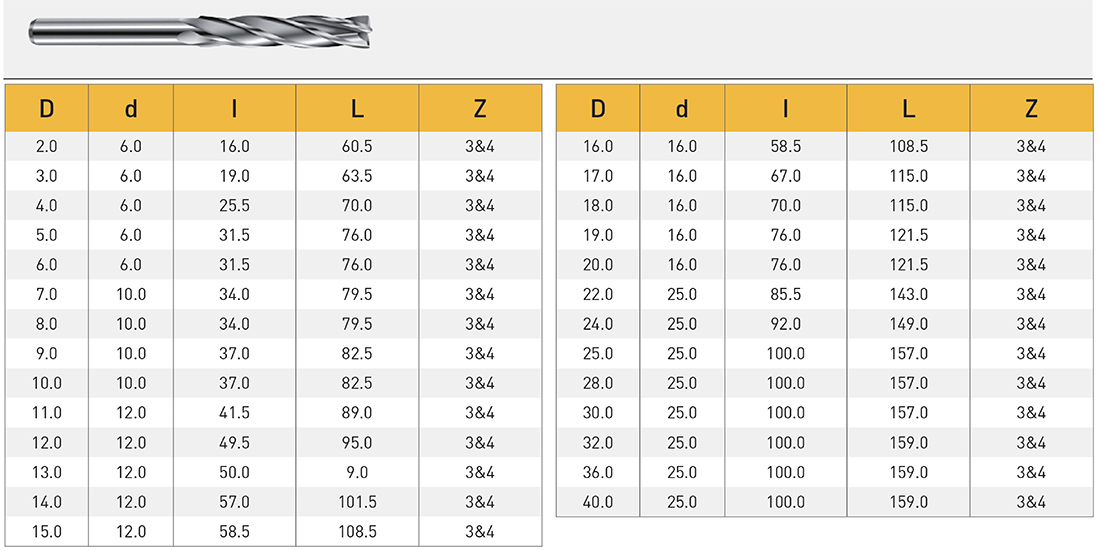

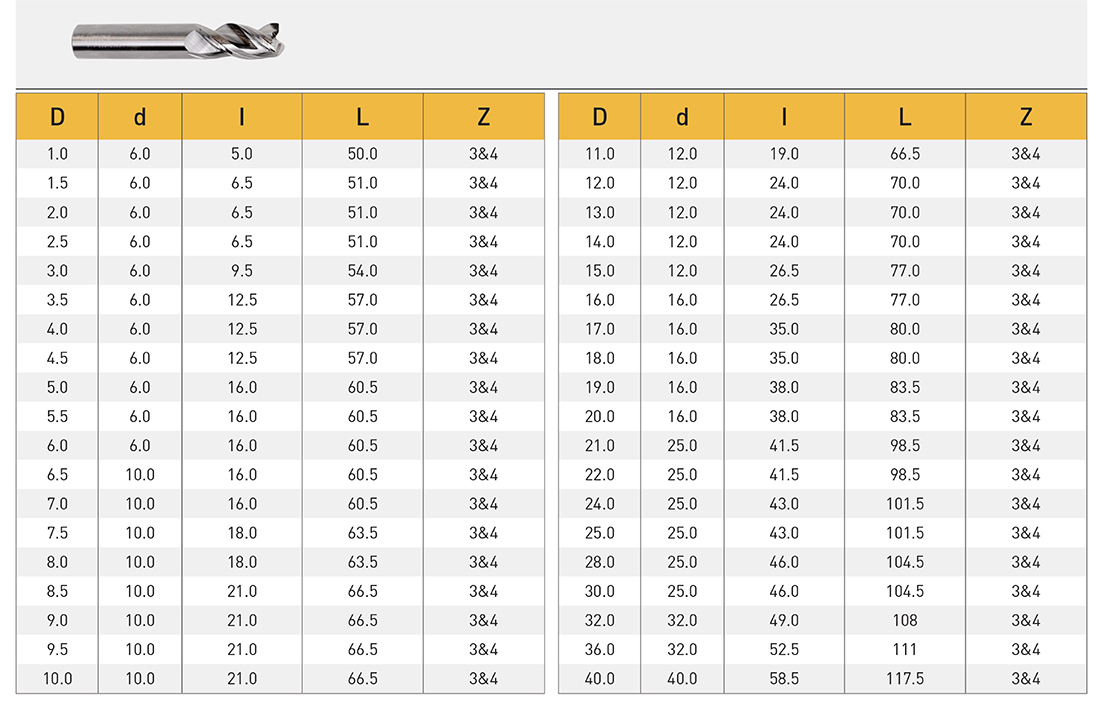

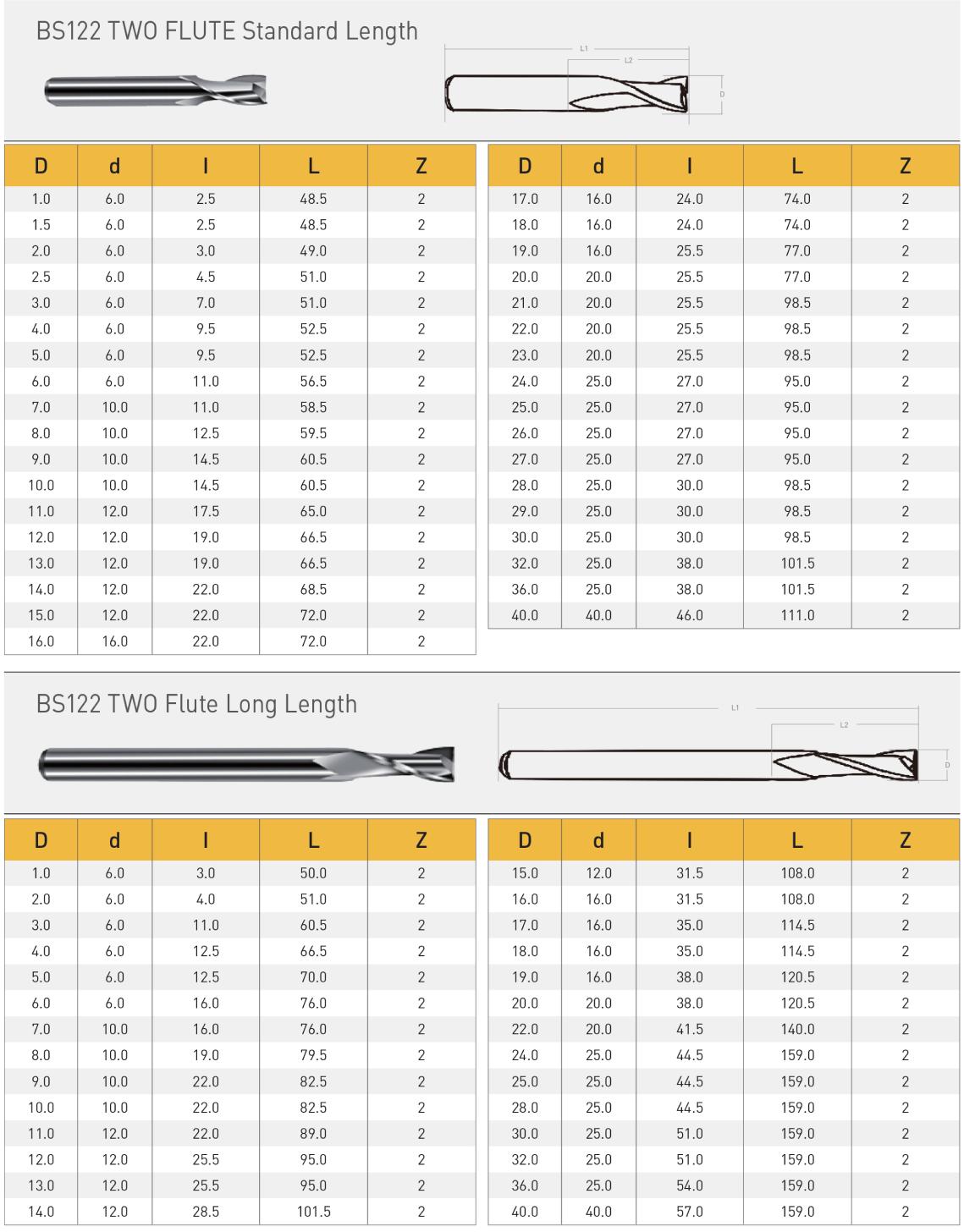

Ubungakanani bemveliso

Ingcaciso yeMveliso

Ukusika kuvelisa ubushushu obuninzi, ngakumbi ngesantya esiphezulu sokusika, nto leyo ebangela ukuba amaqondo obushushu anyuke ngokukhawuleza ngenxa yoko. Ukuba isixhobo asinakho ukumelana nokushisa okulungileyo, siya kulahlekelwa ubunzima baso kumaqondo okushisa aphezulu, okuya kukhokelela ekunciphiseni ukusika ukusebenza kakuhle. Ngaphandle kwamaqondo obushushu aphezulu, ukuqina kwezixhobo zethu zokusika kuhleli kuphezulu, kubavumela ukuba baqhubeke nokusika. Le propati ikwabizwa ngokuba yi-thermohardness okanye ubulukhuni obubomvu. Ukusetyenziswa kwezixhobo zokusika ezichasene nokushisa kuyafuneka ukuze kugcinwe ukusebenza okuzinzile kokusika phantsi kwamaqondo okushisa aphezulu kunye nokukhusela ukushisa okugqithiseleyo ngenxa yokungaphumeleli kwesixhobo.

Abasiki be-cutter kufuneka bakwazi ukujamelana nempembelelo eninzi ngexesha lokusika, ngaphandle koko baya kuphuka ngokulula. Ukongeza kokomelela kunye nokuqina, i-Erurocut milling cutters inobunzima obubalaseleyo. Isisiki sokusila kufuneka siqine ukuze sithintele ukutshiphuza kunye neengxaki zokutshiphu njengoko siya kuchaphazeleka kwaye singcangcazele ngexesha lenkqubo yokusika. Kuphela kuxa izixhobo zokusika zinezi mpawu ziya kuthi zikwazi ukusebenza ngokungaguquguqukiyo nangokuthembeka phantsi kweemeko ezinzima nezitshintshayo zokusika.

Kubalulekile ukulandela iinkqubo zokusebenza ezingqongqo xa ufaka kwaye ulungelelanisa i-milling cutter ukuqinisekisa ukuba i-cutter idibene ne-workpiece kunye ne-angle echanekileyo. Ngenxa yoko, ukusebenza kakuhle kokucubungula kuya kuphuculwa, kunye nomonakalo womsebenzi kunye nokungaphumeleli kwezixhobo kuya kuthintelwa ngenxa yokulungelelaniswa okungafanelekanga.