I-Aluminiyam eNqobileyo ye-Shank Milling Cutter

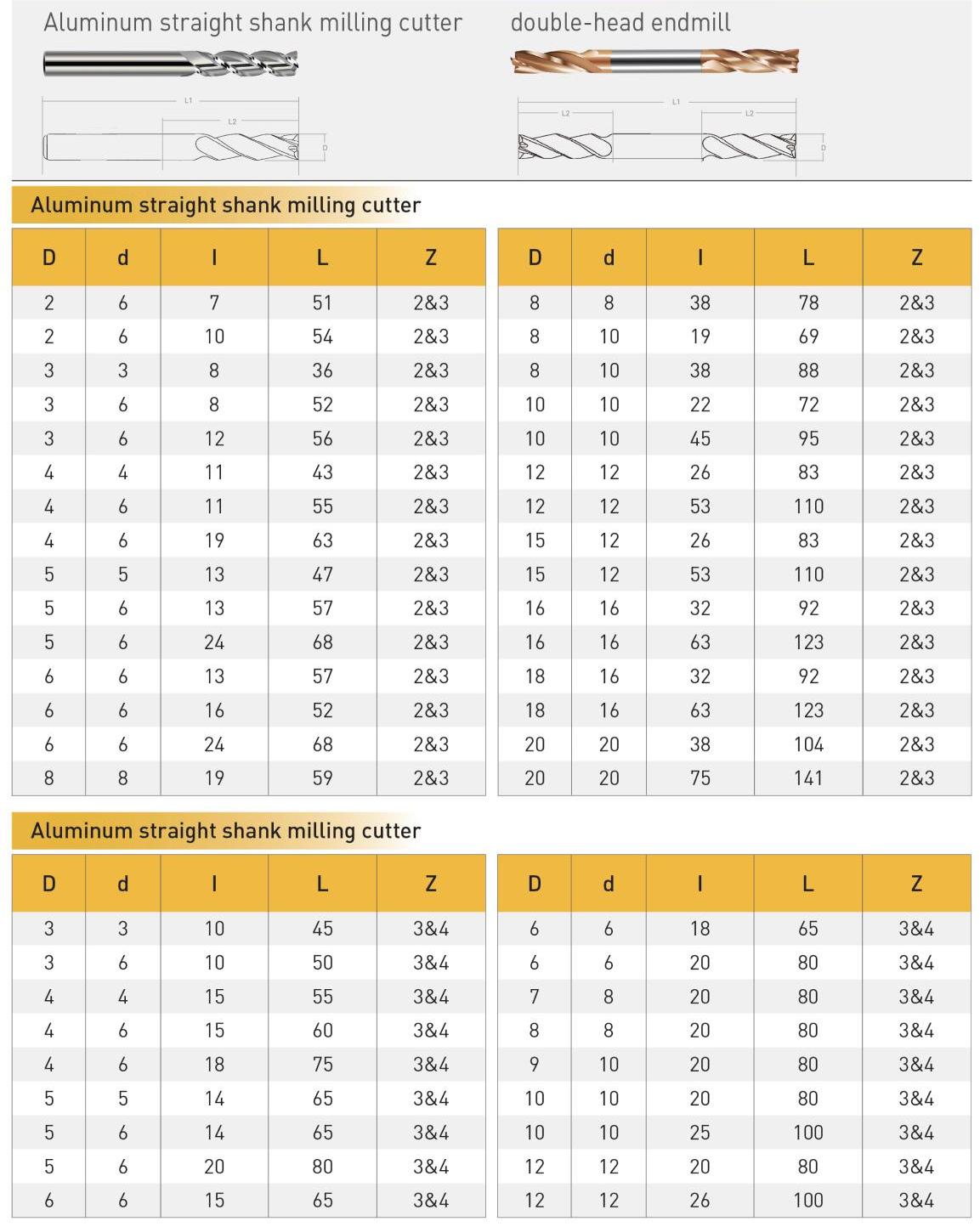

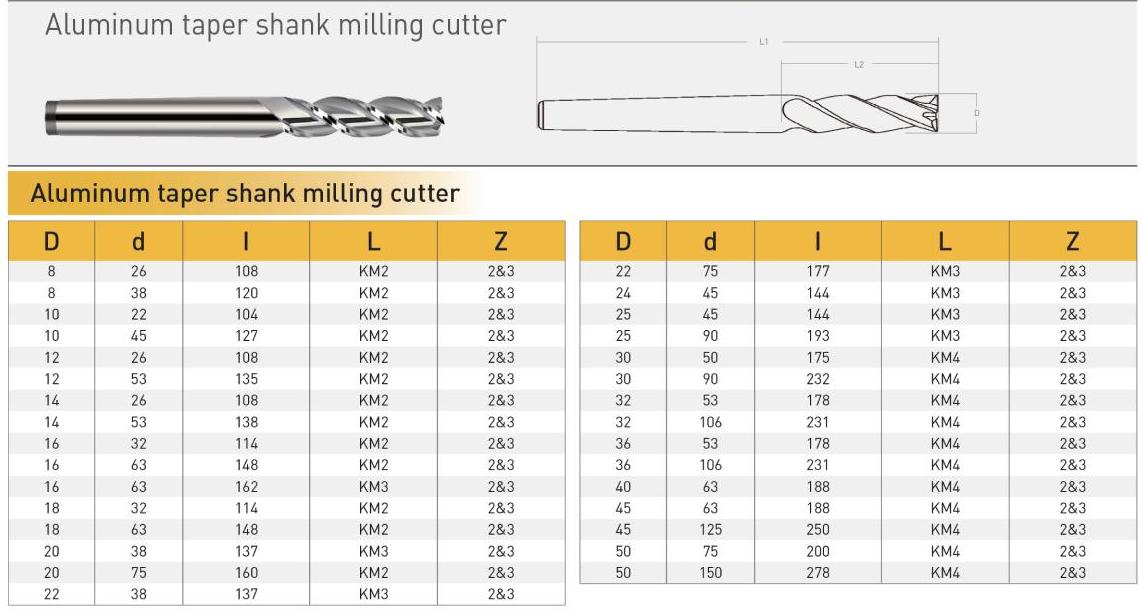

Ubungakanani bemveliso

Ingcaciso yeMveliso

Ukumelana nobushushu kwabasiki be-milling kukwayenye yezinto zayo eziphambili. Ngethuba lenkqubo yokusika, isixhobo sivelisa ubushushu obukhulu, ngakumbi xa isantya sokusika siphezulu, ukushisa kuya kunyuka ngokukhawuleza. Ukuba ukuchasana nokushisa kwesixhobo akukuhle, kuya kulahlekelwa ubunzima bayo kumaqondo aphezulu, okubangela ukuncipha kokusika ukusebenza kakuhle. Izinto zethu zokusika i-milling cutter zinokuxhathisa ubushushu obubalaseleyo, okuthetha ukuba zigcina ukuqina okuphezulu kumaqondo obushushu aphezulu, okubavumela ukuba baqhubeke nokusika. Le propati yobunzima obuphezulu bobushushu bubizwa ngokuba yi-thermohardness okanye ukuqina obomvu. Kuphela ngokuchasana kobushushu obulungileyo kunokugcina isixhobo sokusika esizinzile phantsi kweemeko eziphezulu zokushisa kwaye ugweme ukungaphumeleli kwesixhobo ngenxa yokushisa.

Ukongeza, abasiki be-erurocut milling nabo banamandla aphezulu kunye nokuqina okuhle. Ngethuba lenkqubo yokusika, isixhobo sokusika kufuneka simelane namandla amakhulu, ngoko kufuneka sibe namandla aphezulu, ngaphandle koko kuya kuphuka lula kwaye konakaliswe. Kwangaxeshanye, ngenxa yokuba abasiki be-milling baya kuchaphazeleka kwaye bangcangcazele ngexesha lenkqubo yokusika, kufuneka babe nokomelela okuhle ukunqanda iingxaki ezinje ngetshiphu kunye netshiphu. Kuphela ngale mpahla inokuthi isixhobo sokusika sigcine izakhono zokusika ezizinzile kwaye ezinokwethenjelwa phantsi kweemeko ezinzima kunye neziguquguqukayo zokusika.

Xa ufaka kwaye ulungelelanisa i-cutter yokugaya, amanyathelo okusebenza angqongqo kufuneka athathwe ukuze kuqinisekiswe uqhagamshelwano oluchanekileyo kunye ne-angle yokusika phakathi kwe-milling cutter kunye ne-workpiece. Oku akuncedi nje ukuphucula ukusebenza kakuhle, kodwa kunqanda umonakalo we-workpiece okanye ukusilela kwezixhobo okubangelwa ukulungiswa okungafanelekanga.