T29 Less Noise and Sparks Flap Disc

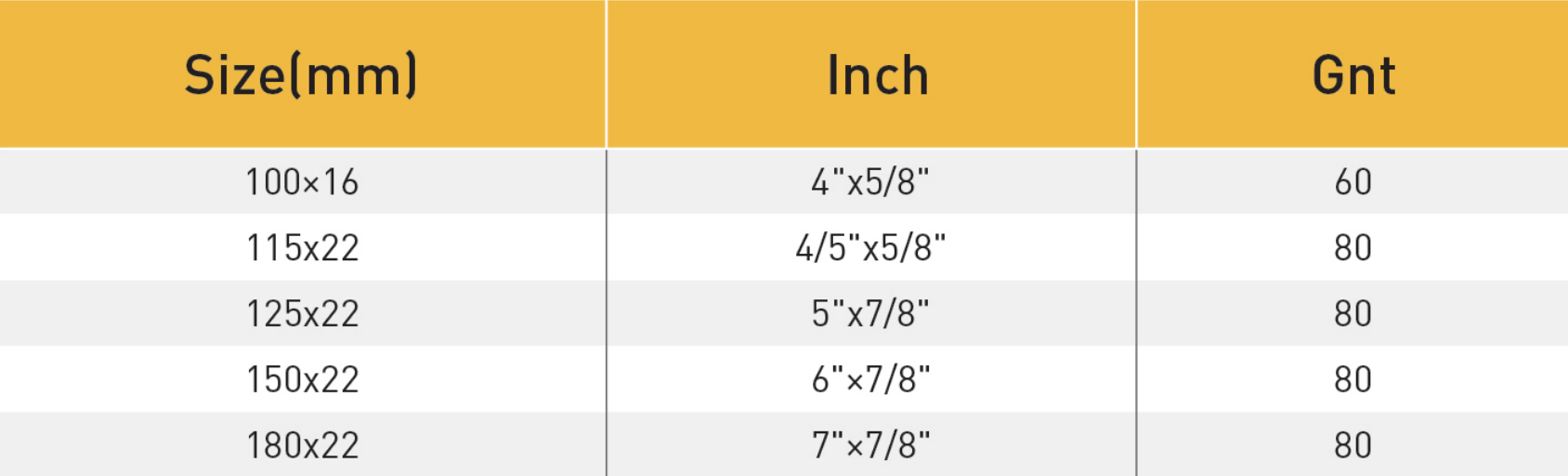

Product Size

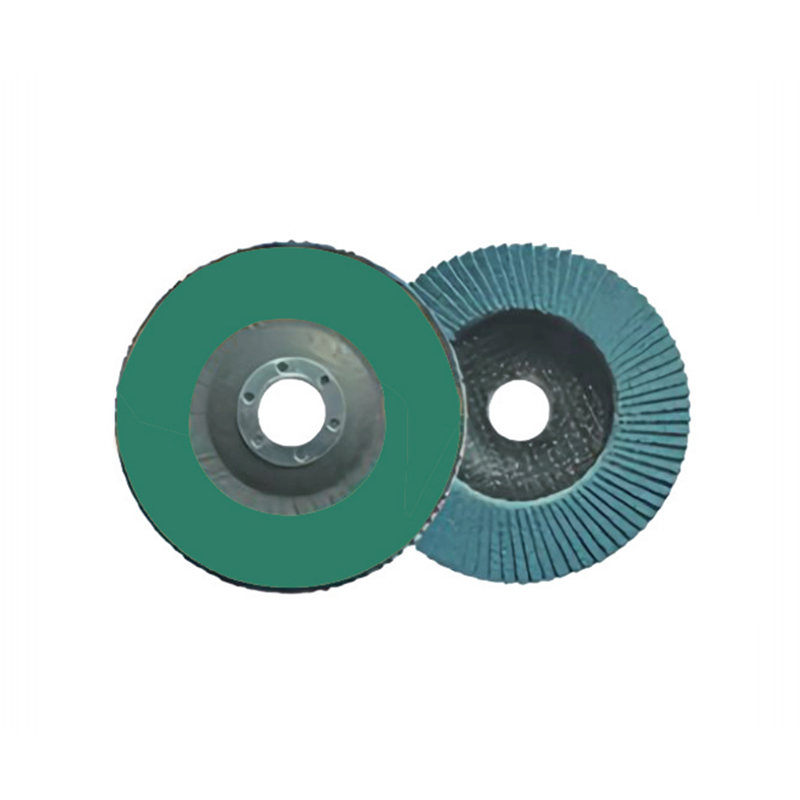

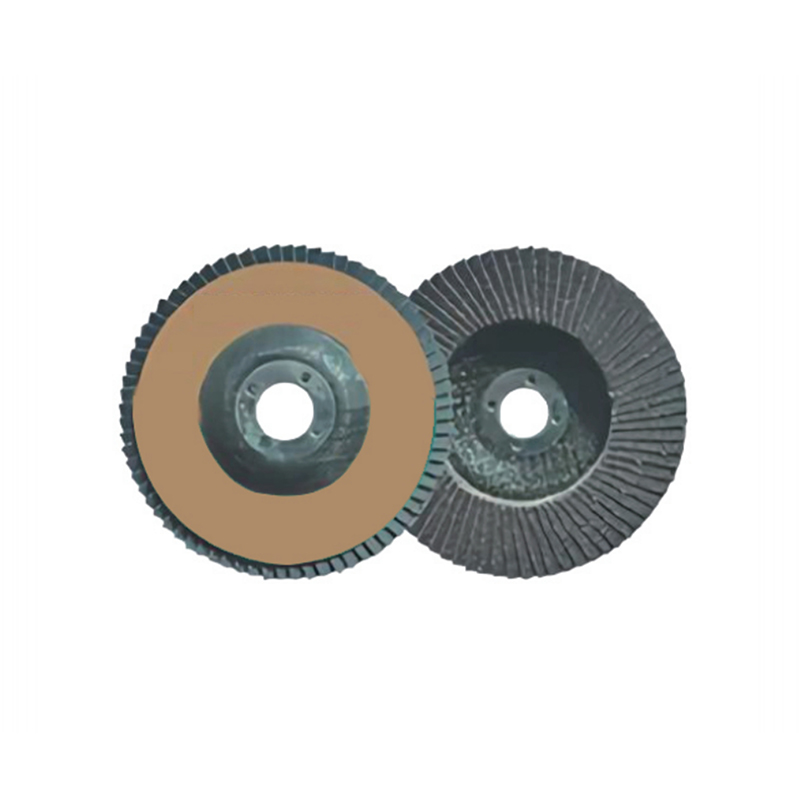

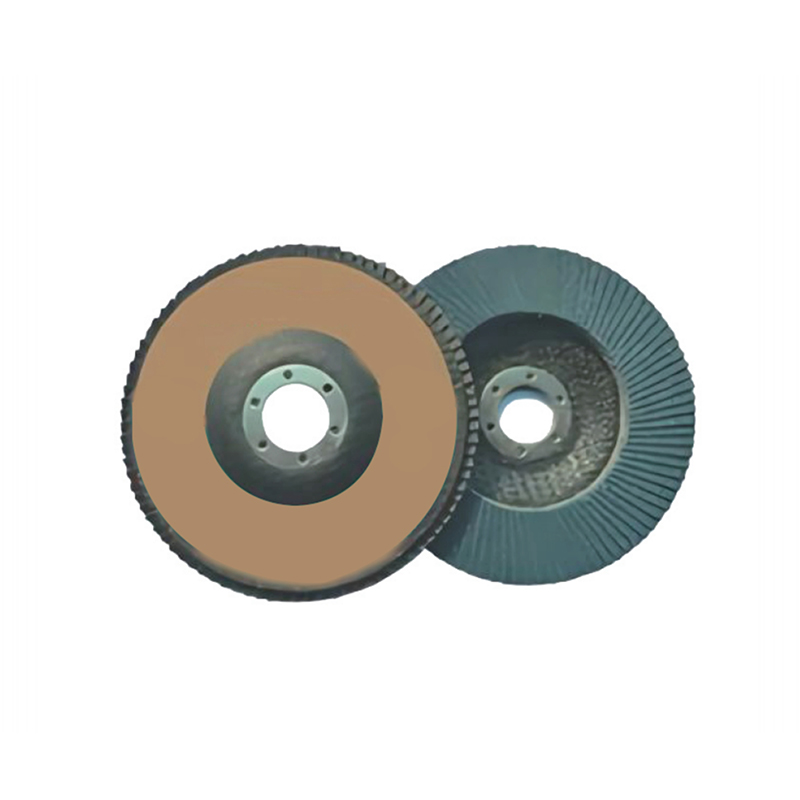

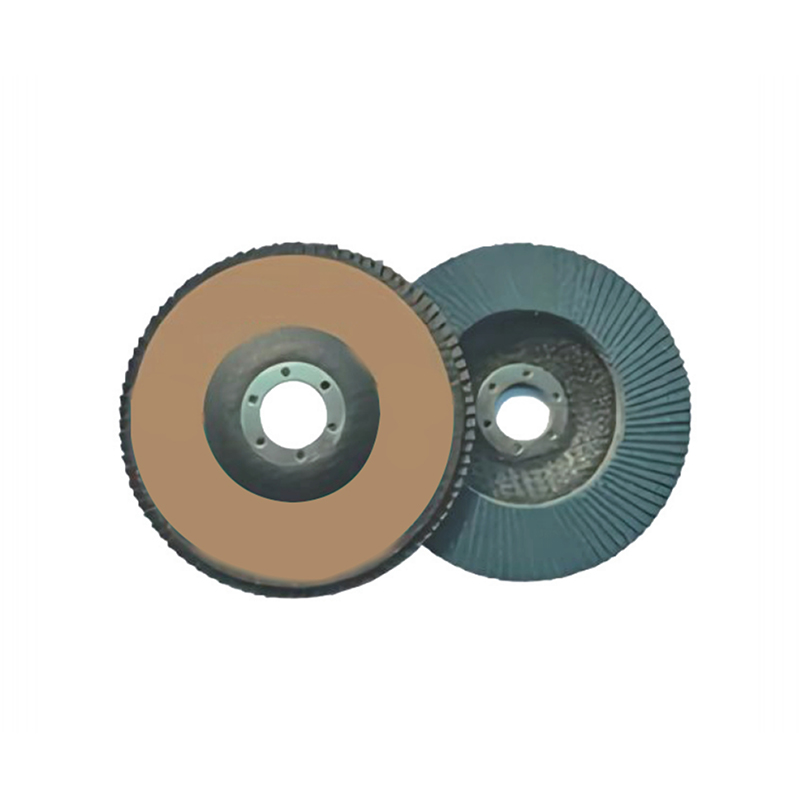

Product Show

A low vibration system reduces operator fatigue. Stainless steel, non-ferrous metals, plastics, paints, wood, steel, mild steel, ordinary tool steel, cast iron, steel plates, alloy steel, special steel, spring steel are among the materials that can be ground with this machine. High quality, stable and long-lasting surface finish, fast speed, good heat dissipation, and no pollution. As an alternative to bonded wheels and fiber sanding discs, it is a cost-effective and time-saving option for a wide variety of applications, especially when gouging resistance and final finish are crucial. It is possible to maximize the utilization of blind blades by selecting the right blind blades for weld grinding, deburring, rust removal, edge grinding, and weld blending. It is possible to adapt louver wheels to the cutting of materials with varying strengths since they have a relatively strong cutting force. The hardness and long service life of this cutting machine are several times higher than those of tablet products, so it can also be used for grinding and polishing large pieces of equipment. Compared with similar cutting machines, it is much more durable and heat-resistant.

It is possible to overload and overheat louver blades with excessive use, which results in faster wear and reduced effectiveness of the abrasives. Furthermore, if the louver blade doesn't engage enough metal to grind it effectively, the grinding process will take longer and the surface will become more worn. Venetian blind blades work at an angle. Depending on what you are making and grinding, you will need to adjust the angle. It is typical to have a horizontal or horizontal angle of five to ten degrees. It is possible for excess blade particles to connect with the metal if the angle is too flat. In some blind blades, excessive wear and inadequate polish can result from an angle that is too large. This can result in excessive wear and an insufficient polish.