Din338 Ngurangan HSS Bor Bit

Produk Témbongkeun

| Bahan | 4241,4341, M2, M35, M42 |

| Standar | DIN 338 |

| Prosés | Taneuh pinuh, Satengah taneuh, Gulung taneuh |

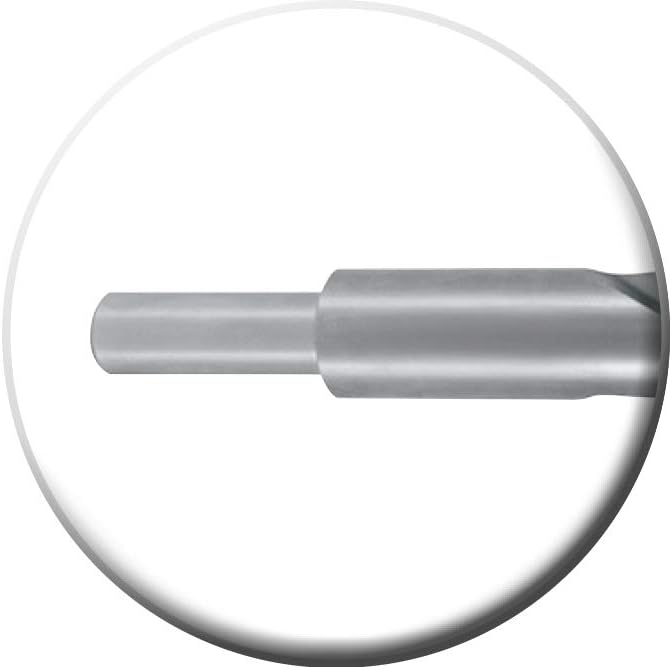

| Shank | Ngurangan latihan shank |

| Gelar | 135 ° Split Point atawa 118 ° Pilot Point |

| Beungeut | Amber, Hideung, Caang, Ganda, Pelangi, Timah coated |

| Pamakéan | |

| Stainless steel, Metal pangeboran, Aluminium, PVC jsb. | |

| Disaluyukeun | OEM, ODM |

| Bungkusan | 10/5 PCS dina kantong PVC, kotak plastik, individual dina kartu kulit, ganda molotok, Clamshell. |

Baja-speed tinggi nyaéta bahan dipaké. Baja-speed tinggi ieu diperlakukeun panas dina raraga ngaronjatkeun karasa, kakuatan tensile sarta hirup motong na kana waktu. Saterusna, desain tip bor urang teu ngan nyadiakeun stabilitas tinggi na precision, tapi ogé seukeutna gambar jeung ciri non-dieunakeun, anu dina gilirannana manjangkeun umur layanan na. A sabeulah pre-cut cleans edges of liang , bari pituduh pungkur dual ensures akurasi tinggi. Mata bor anu kaku, ngarah moal ngabengkokkeun kawas bit bor panjang.

Salian ujung pahat tapered baku, suling chip sarta ujung balik kacida rounded dirancang husus pikeun pangeboran logam, hasilna tepat, liang beresih. Bor Ieu pisan awét sarta adaptable kalawan desain cecekelan ngurangan nu pas ogé sarta moal gampang pegat. Salian ngaronjatkeun kinerja sarta efisiensi, desain Rotary naek speeds pangeboran. Perlakuan permukaan nyegah karat sareng ngagem. Lamun anjeun boga liang tina ukuran husus, bor ieu ngurangan gaya dorong ku 50%, mastikeun liang buleud sampurna. shank nu ngurangan rotasi dina cuk, sarta bit shank ditandaan pikeun idéntifikasi ukuran gampang.

Ukuran

| Dia | L2 | L1 | d | ||

| 10.5 | 87 | 133 | 10.0 | ||

| 11 | 94 | 142 | 10.0 | ||

| 11.5 | 94 | 142 | 10.0 | ||

| 12 | 101 | 151 | 10.0 | ||

| 12.5 | 101 | 151 | 10.0 | ||

| 13 | 101 | 151 | 10.0 | ||

| 13.5 | 108 | 160 | 10.0 | ||

| 13.5 | 108 | 160 | 13.0 | ||

| 14 | 108 | 160 | 10.0 | ||

| 14 | 108 | 160 | 13.0 | ||

| 14.5 | 114 | 169 | 10.0 | ||

| 14.5 | 114 | 169 | 13.0 | ||

| 15 | 114 | 169 | 10.0 | ||

| 15 | 114 | 169 | 13.0 | ||

| 15.5 | 120 | 178 | 10.0 | ||

| 10.5 | 87 | 133 | 10.0 | ||

| 11 | 94 | 142 | 10.0 | ||

| 11.5 | 94 | 142 | 10.0 | ||

| 12 | 101 | 151 | 10.0 | ||

| 12.5 | 101 | 151 | 10.0 | ||

| 13 | 101 | 151 | 10.0 | ||

| Dia | L2 | L1 | d | ||

| 13.5 | 108 | 160 | 10.0 | ||

| 13.5 | 108 | 160 | 13.0 | ||

| 14 | 108 | 160 | 10.0 | ||

| 14 | 108 | 160 | 13.0 | ||

| 14.5 | 114 | 169 | 10.0 | ||

| 14.5 | 114 | 169 | 13.0 | ||

| 15 | 114 | 169 | 10.0 | ||

| 15 | 114 | 169 | 13.0 | ||

| 15.5 | 120 | 178 | 10.0 | ||

| 15.5 | 120 | 178 | 13.0 | ||

| 16 | 120 | 178 | 10.0 | ||

| 16 | 120 | 178 | 13.0 | ||

| 16.5 | 125 | 184 | 10.0 | ||

| 16.5 | 125 | 184 | 13.0 | ||

| 17 | 125 | 184 | 10.0 | ||

| 17 | 125 | 184 | 13.0 | ||

| 17.5 | 130 | 191 | 13.0 | ||

| 18 | 130 | 191 | 10.0 | ||

| 18 | 130 | 191 | 13.0 | ||

| 18.5 | 135 | 198 | 13.0 | ||

| 19 | 135 | 198 | 13.0 | ||

| 19.5 | 140 | 205 | 13.0 | ||

| 20 | 140 | 205 | 10.0 | ||

| 20 | 140 | 205 | 13.0 | ||