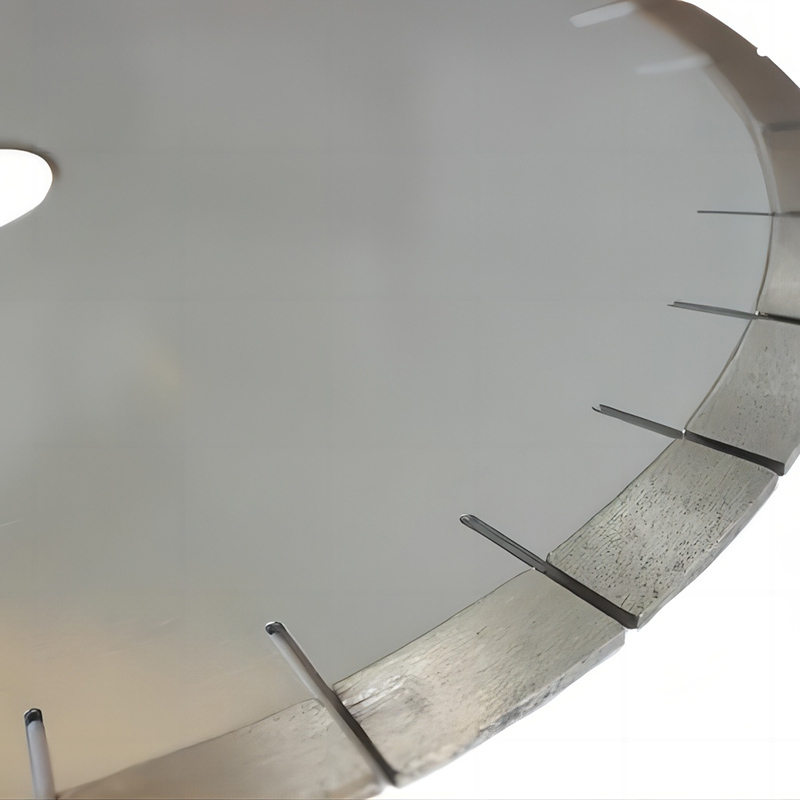

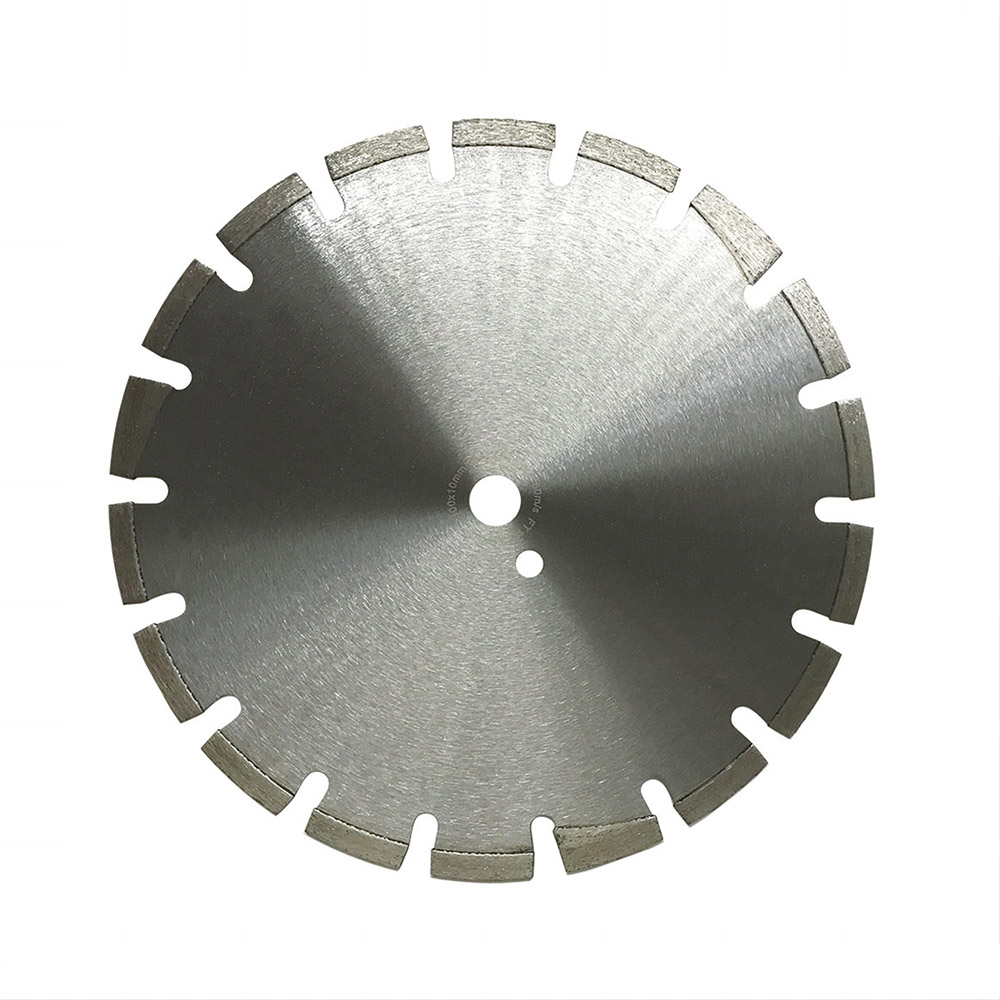

U Shape Segment Saw Blade

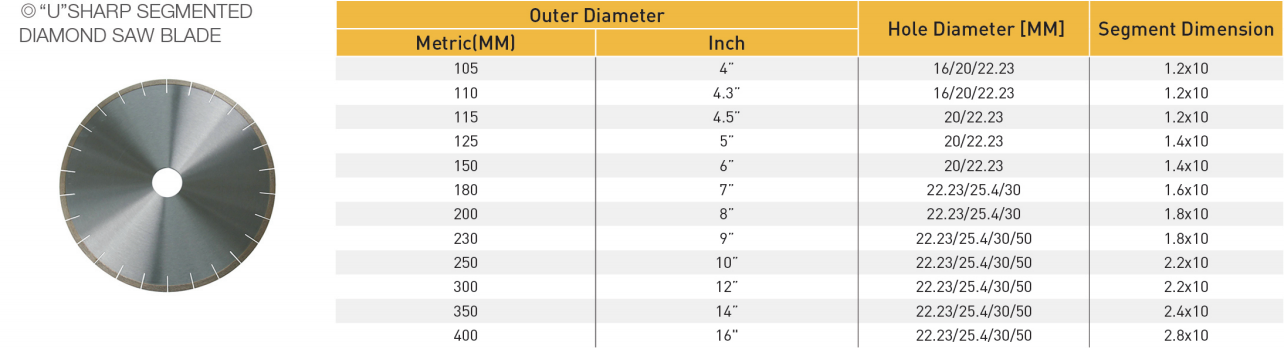

Boholo ba Sehlahisoa

Tlhaloso ea Sehlahisoa

•Moqapi oa hlooho ea sehahi o fana ka ts'ireletso ea undercut, ka katleho ho thibela ho roala pele ho nako kapa ho hloleha ha hlooho ea seha, ka hona e lelefatsa bophelo ba ts'ebeletso ea lehare la sakha. Moralo o ikhethileng oa DEEP U tooth groove o etsa hore moea o pholileng o be betere mme lichipisi li ka kheloha hamolemo, ho ntlafatsa ts'ebetso ea lehare la sakha. E lumellana le lisakha tse ngata tse tšoaroang ka letsoho le lisakha tsa push, ho etsa hore ho be bonolo ho e sebelisa lapeng kapa mosebetsing. Motsoako oa tšepe o nang le lebelo le phahameng o 'nile oa phekoloa ka mocheso ho ba le matla a phahameng le ho hanyetsa ho apara ka mokhoa o phahameng,' me o ka mamella litlhoko tsa ho itšeha ho omme, ho etsa bonnete ba hore lehare la saw le ka boloka ts'ebetso e ntle tlas'a tšebeliso ea nako e telele. E entsoe ka emery e phahameng haholo, e etselitsoeng ka ho khetheha lisebelisoa tse thata tse kang konkreite, ho etsa bonnete ba ho itšeha ka boreleli ka ho apara ho fokolang. Theknoloji e tsoetseng pele ea welding ea laser e sebelisoa ho etsa hore hlooho ea sehahi e be matla le ho tšoarella ho feta, e leng ho eketsang bophelo ba ho itšeha. E loketse ho khaola ho omileng kapa ho koloba, ho khaola ho omileng ho tiisa liphello tse boreleli, ha ho itšeha ka metsi ho boloka nako le boiteko.

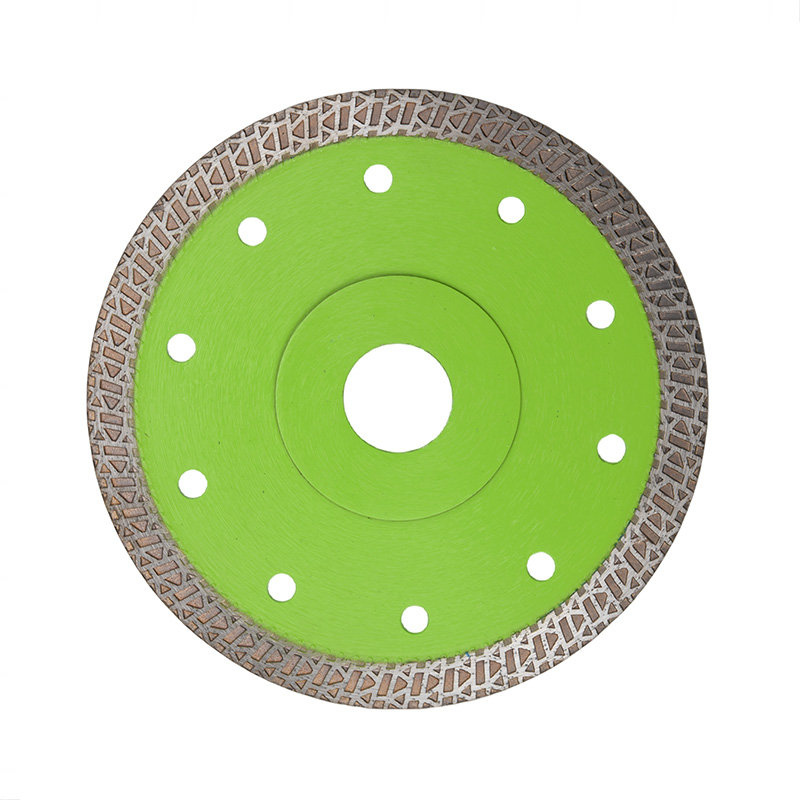

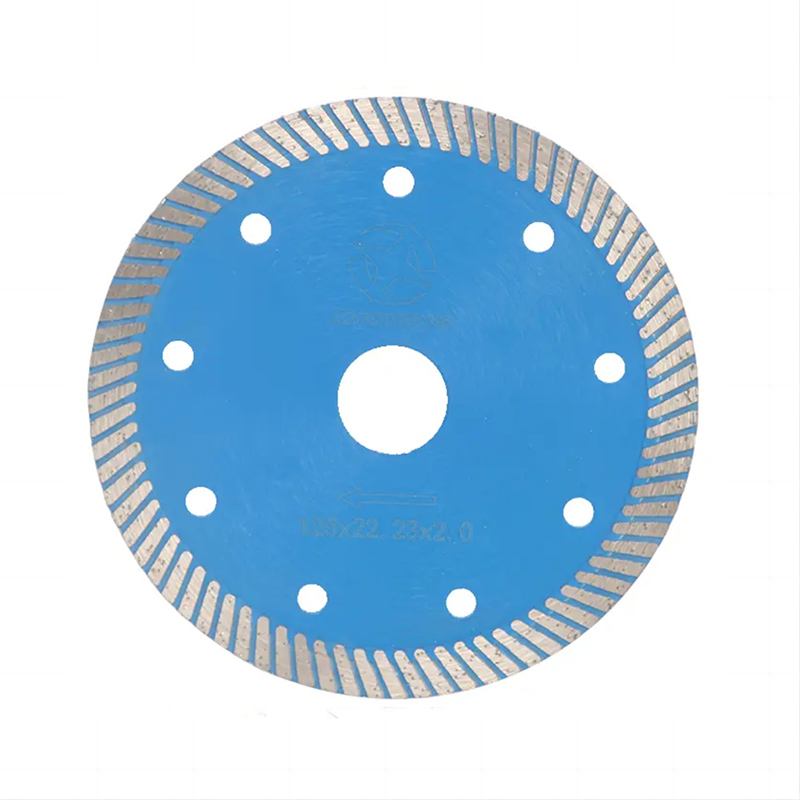

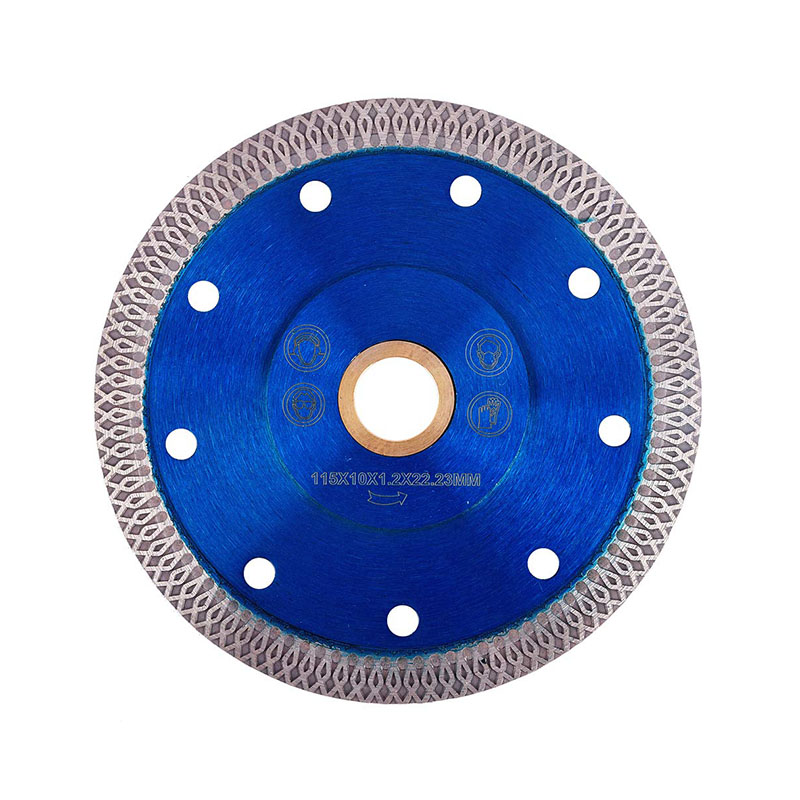

• Ka lehare la sedikadikwe la sedikadikwe, o ka etsa sehokelo ntle le chip mme e tla nka nako e telele mme e sebetse hantle ho feta mahare a mang a taemane. Li-blades tsa daemane li ka sebelisoa li le metsi kapa li omme, empa li sebetsa hantle ha li sebelisoa le metsi. Li entsoe ka litaemane tsa boleng bo phahameng ka ho fetisisa le matrix a premium bonding ho netefatsa ts'ebetso ea nako e telele. Lebelo la ho itšeha ka potlako, le tiile ebile le tšoarella. Ka lebaka la li-grooves tse ka har'a lehare la sakha ea daemane, phepelo ea moea e ea ntlafala mme lerōle, mocheso le seretse lia qhalana ho netefatsa ts'ebetso e nepahetseng ea ho itšeha.