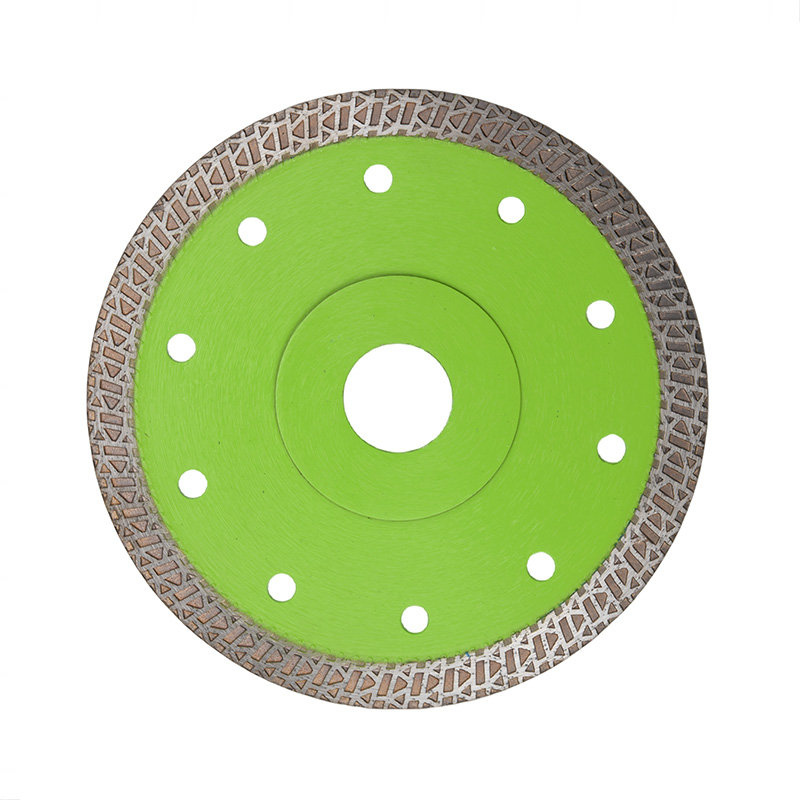

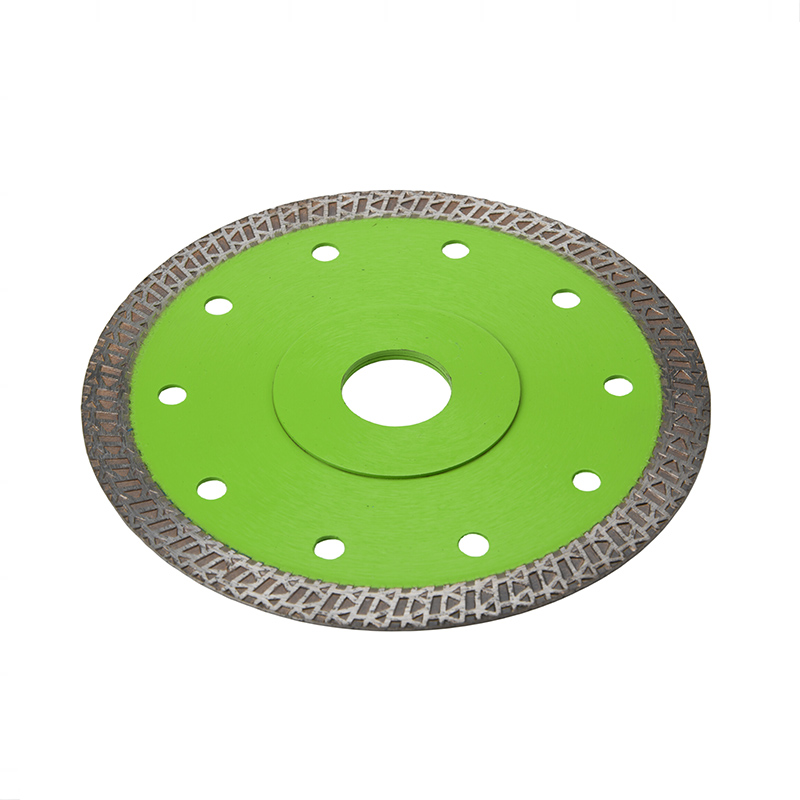

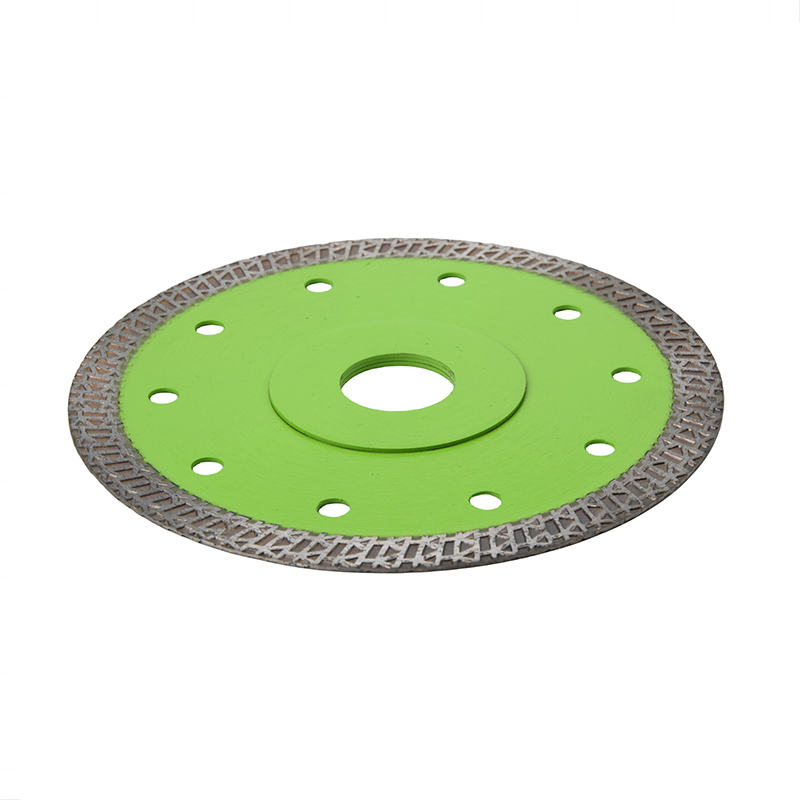

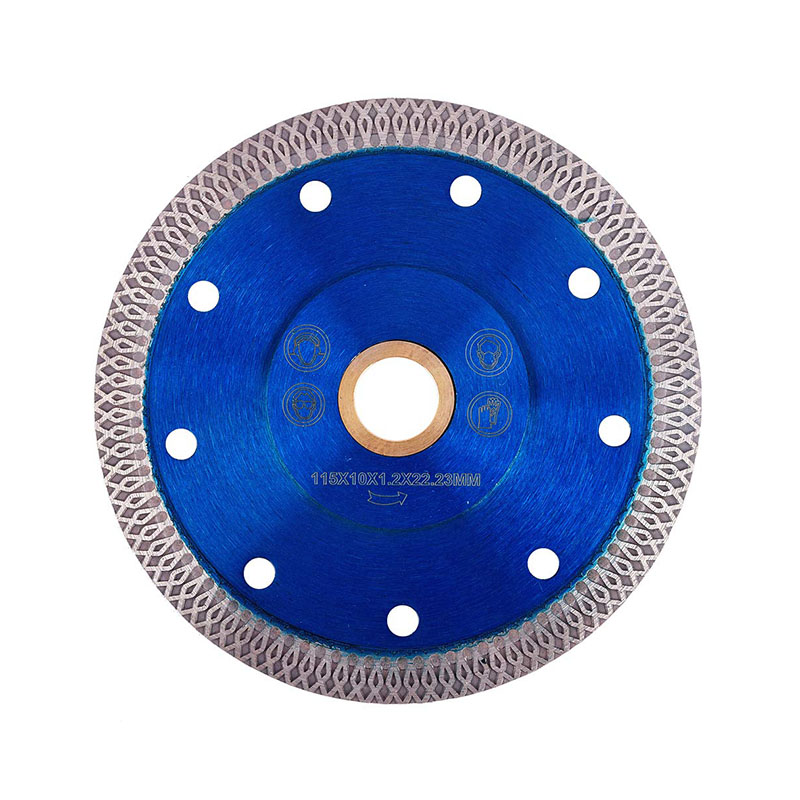

Turbo Saw Blade e nang le Flange

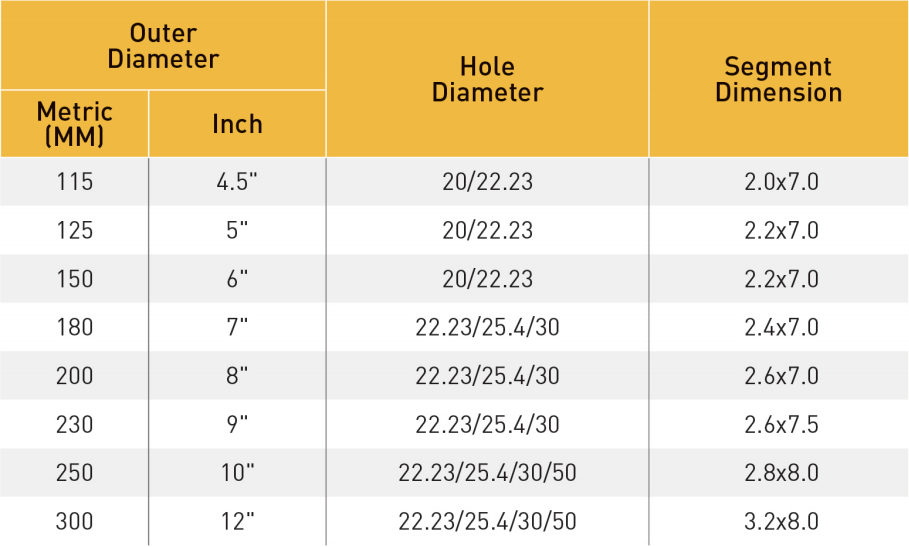

Boholo ba Sehlahisoa

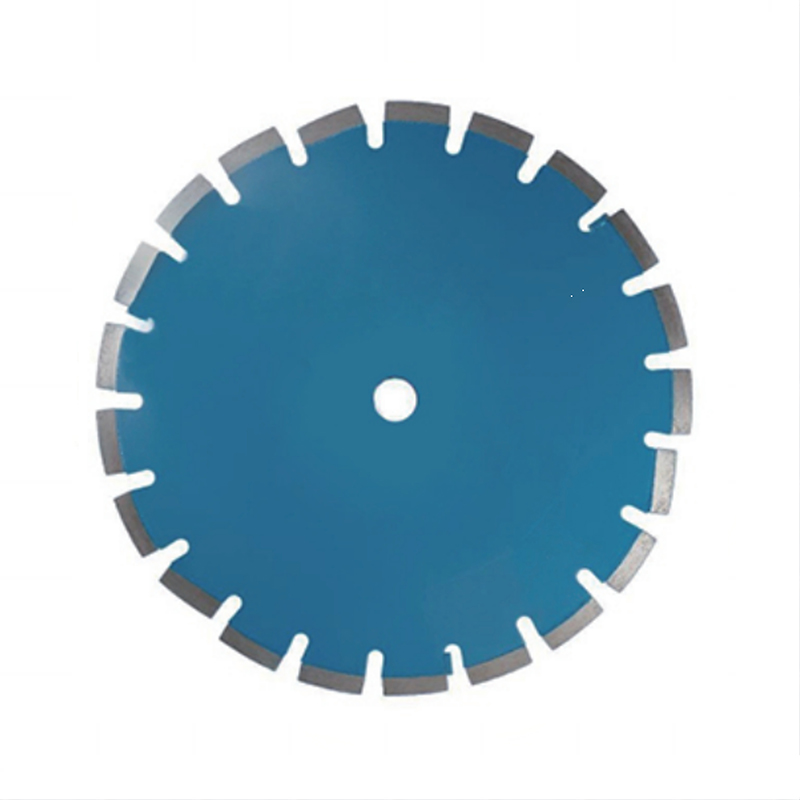

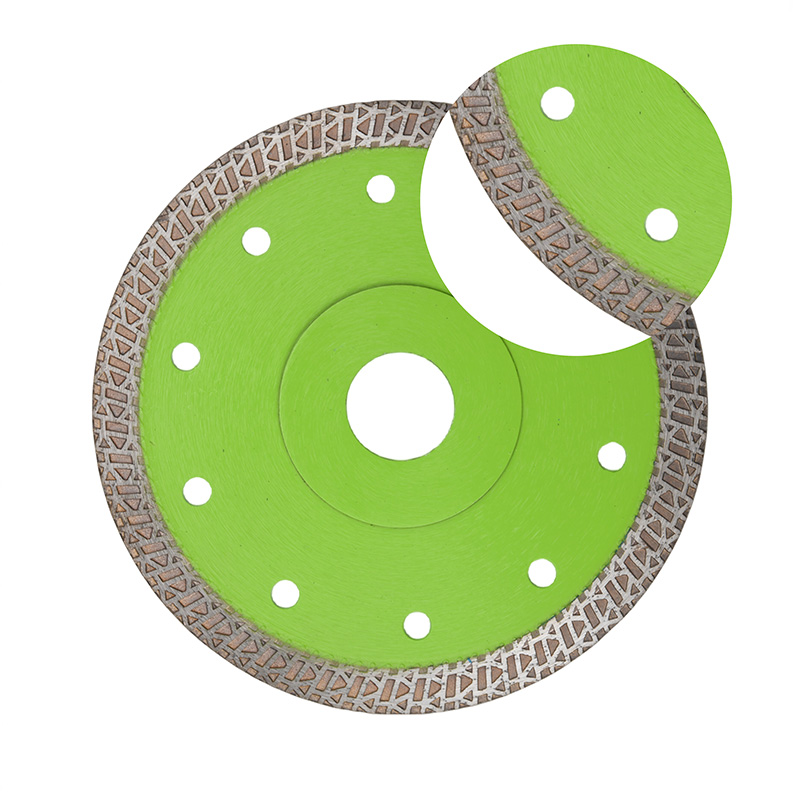

Pontšo ea Sehlahisoa

Li-blades tsena li na le karolo e moqotetsane ea turbine e hlahisang likhahla tse boreleli, tse potlakileng ntle le ho phunya ha granite e ommeng kapa majoe a mang a thata. Lihlooho tse matlafalitsoeng li nka nako e telele 'me li khaola ka potlako, li u pholosa nako e ngata. Ka ho kenyelletsa li-ring ring tse matlafalitsoeng mahlakoreng ka bobeli a lehare, ho khaola ho tsitsitse haholoanyane 'me ho fella ka qetello e molemo. Li-substrates tsa litaemane li fana ka bophelo bo bolelele, bo se nang mathata le litefiso tse phahameng tsa ho tlosa thepa. Substrate ea daemane e teteaneng bohareng ho thibela ho sisinyeha le ho sisinyeha.

Li-blade tsa rona tsa daemane li boreleli ka 30% ho feta li-blade tsa karolo ka lebaka la matrix a tlamahano a nepahetseng a fanang ka maqeba a potlakileng, a tšoarellang le a boreleli. Maemo a leano la likarolo tsa turbine a netefatsa ho pholisa hantle, ka hona ho thibela ho futhumala ho feteletseng le ho lelefatsa bophelo ba ts'ebeletso ea eona. Lisebelisoa tsena tsa grinder angle tsa daemane li entsoe ka tšepe ea alloy e matla haholo 'me li koahetsoe ka matrix a daemane ho netefatsa hore ha ho na litlhase kapa matšoao a chesang ha ho seha thepa e thata. Li ikotla ha li ntse li seha ka ho phumula lehlabathe la taemane ha li ntse li sebetsa.

Karolo e ka thōko ea turbine ea mesh e thusa ho pholile le ho tlosa lerōle, ho fokotsa litšila le ho fana ka sehiloeng se hloekileng, se boreleli bakeng sa ponahalo ea setsebi haholoanyane. Ka ho fokotsa ho thothomela nakong ea ho itšeha, e ntlafatsa matšeliso le taolo ea mosebedisi, e leng se fellang ka phihlelo e monate le e nepahetseng ea ho itšeha. Tšepe ea mantlha e matlafalitsoeng le flange e matlafalitsoeng e fana ka botsitso bo boholo le ho itšeha ka ho otloloha.