Ke engTwist Drills?

Twist drill ke lentsoe le akaretsang bakeng sa mefuta e fapaneng ea liboro, joalo ka liboro tsa tšepe, liboro tsa polasetiki, liboro tsa patsi, liboro tsa bokahohleng, masonry le liboro tsa konkreite. Li-drill tsohle tsa twist li na le tšobotsi e tšoanang: Mekolilo ea helical e fang liboro mabitso a tsona. Li-drill tse fapaneng tsa twist li sebelisoa ho latela boima ba thepa e lokelang ho etsoa.

Ka lehlakoreng la helix

Mofuta oa N

●E loketse lisebelisoa tse tloaelehileng tse kang tšepe ea tšepe.

●Mofuta oa N cut wedge o na le mekhoa e mengata ka lebaka la ho sotha ha oona oa hoo e ka bang. 30°.

Sebaka sa ntlha sa mofuta ona ke 118 °.

Mofuta oa H

●E loketse lisebelisoa tse thata le tse brittle tse kang boronse.

●Mofuta oa H helix angle o pota 15°, e leng se etsang hore ho be le angle e kholo ea wedge e nang le bohale bo fokolang empa bo tsitsitseng haholo.

●Li-drill tsa mofuta oa H li boetse li na le ntlha ea 118 °.

Mofuta oa W

●E sebelisoa bakeng sa lisebelisoa tse bonolo joalo ka aluminium.

●Helix angle ea hoo e ka bang. 40° e fella ka sekhutlo se senyenyane sa wedge bakeng sa ho itšeha ho bohale empa ho sa tsitsang ha ho bapisoa.

●Sebaka sa ntlha ke 130 °.

Ka lintho tse bonahalang

High Speed Steel (HSS)

Thepa e ka aroloa ka mefuta e meraro: tšepe e lebelo le phahameng, tšepe e nang le cobalt e nang le tšepe e phahameng le carbide e tiileng.

Ho tloha ka 1910, tšepe ea lebelo le phahameng e 'nile ea sebelisoa e le sesebelisoa sa ho itšeha ka lilemo tse fetang lekholo. Hona joale ke thepa e sebelisoang ka ho fetisisa le e theko e tlaase ka ho fetisisa bakeng sa lisebelisoa tsa ho itšeha. Li-drill tsa tšepe tse lebelo le phahameng li ka sebelisoa liborong tsa matsoho ka bobeli le tikolohong e tsitsitseng e kang mochini oa ho phunya. Lebaka le leng leo ka lona tšepe ea lebelo le phahameng e tšoarellang nako e telele e ka 'na ea e-ba hobane lisebelisoa tsa ho itšeha ka lebelo le phahameng li ka etsoa khafetsa. Ka lebaka la theko ea eona e tlase, ha e sebelisoe feela ho cheka li-drillbits, empa hape e sebelisoa haholo ho fetolela lisebelisoa.

Cobalt-Containing High-Speed Steel (HSSE)

Tšepe e nang le cobalt e nang le lebelo le phahameng e na le boima bo betere le boima bo bofubelu ho feta tšepe e phahameng. Ho eketseha ha boima ho boetse ho ntlafatsa ho hanyetsa ha eona ho apara, empa ka nako e ts'oanang ho nyehela karolo ea boima ba eona. E ts'oanang le tšepe ea lebelo le phahameng: li ka sebelisoa ho eketsa palo ea linako ka ho sila.

Carbide (CARBIDE)

Cementcarbide ke lisebelisoa tse entsoeng ka tšepe tse entsoeng ka tšepe. Har'a tsona, tungsten carbide e sebelisoa e le matrix, 'me lisebelisoa tse ling li sebelisoa e le li-binders ho sinter ka ho tobetsa ho chesang ha isostatic le letoto la lits'ebetso tse rarahaneng. Ha ho bapisoa le tšepe e phahameng ka potlako ho latela boima, boima bo bofubelu le ho hanyetsa ho apara, e ntlafalitsoe haholo. Empa litšenyehelo tsa lisebelisoa tsa ho itšeha tsa carbide le tsona li theko e boima haholo ho feta tšepe e lebelo le holimo. Carbide e entsoeng ka samente e na le melemo e mengata ho feta lisebelisoa tse fetileng tsa lisebelisoa mabapi le bophelo ba lisebelisoa le lebelo la ho sebetsa. Ho sila ha lisebelisoa khafetsa, lisebelisoa tsa ho sila tsa litsebi lia hlokahala.

Ka ho roala

A sa koaheloe

Li-coating li ka aroloa ka mefuta e mehlano e latelang ho latela boholo ba tšebeliso:

Lisebelisoa tse sa koahetsoeng ke tsona tse theko e tlaase 'me hangata li sebelisetsoa ho sebetsana le lisebelisoa tse bonolo tse kang alloy ea aluminium le tšepe e tlaase ea carbon.

Ho roala ha oxide e ntšo

Liaparo tsa oksijene li ka fana ka lubricity e ntle ho feta lisebelisoa tse sa koaheloang, hape li betere ho oxidation le ho hanyetsa mocheso, 'me li ka eketsa bophelo ba tšebeletso ka ho feta 50%.

Ho roala ha Titanium Nitride

Titanium nitride ke thepa e atileng haholo ea ho roala, 'me ha e tšoanelehe bakeng sa lisebelisoa tse thata haholo le mocheso o phahameng oa ho sebetsa.

Titanium Carbonitride Coating

Titanium carbonitride e entsoe ho tloha ho titanium nitride, e na le mocheso o phahameng oa ho hanyetsa le ho hanyetsa ho apara, hangata e pherese kapa e putsoa. E sebelisoa ka har'a pokello ea mesebetsi ea Haas ho etsa lisebelisoa tsa mochini tse entsoeng ka tšepe e entsoeng ka tšepe.

Titanium Aluminium Nitride Coating

Titanium aluminium nitride e hanyetsana haholo le mocheso o phahameng ho feta liaparo tsohle tse ka holimo, kahoo e ka sebelisoa libakeng tse phahameng tsa ho itšeha. Ka mohlala, ho sebetsa li-superalloys. E boetse e loketse ts'ebetso ea tšepe le tšepe e sa hloekang, empa kaha e na le likarolo tsa aluminium, lik'hemik'hale tsa lik'hemik'hale li tla etsahala ha ho etsoa aluminium, kahoo qoba lisebelisoa tsa ho sebetsa tse nang le aluminium.

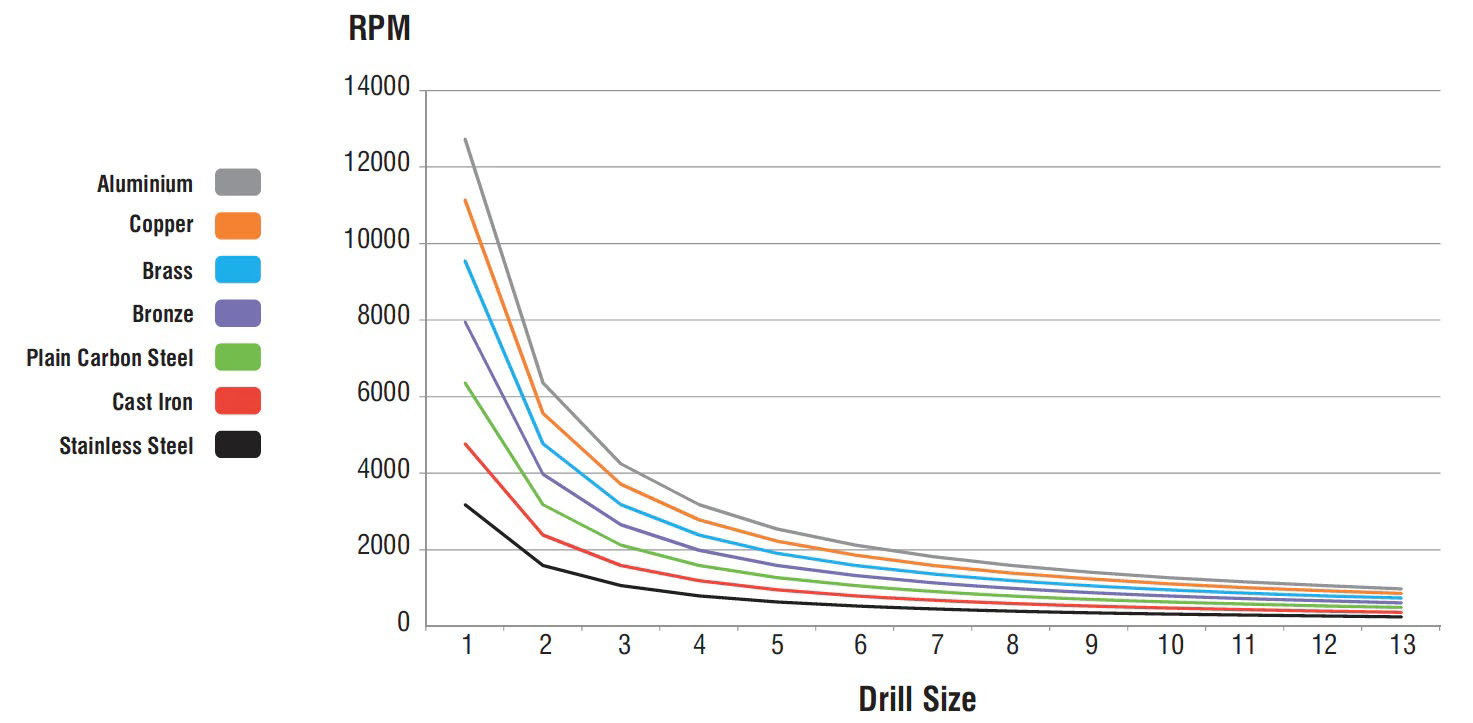

E khothalelitsoeng ho cheka Lebelo ka Metal

| Size ea ho cheka | |||||||||||||

| 1MM | 2MM | 3MM | 4MM | 5MM | 6MM | 7MM | 8MM | 9MM | 10MM | 11MM | 12MM | 13MM | |

| TS'ELISOTŠEPILE | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| NTS'EPE TŠEPE | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| THABANGKHABANETŠEPILE | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 | 795 | 707 | 636 | 579 | 530 | 490 |

| BOROPO | 7955 | 3977 | 2652 | 1989 | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| KOROPO | 9545 | 4773 | 3182 | 2386 | 1909 | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| KOPI | 11136 | 5568 | 3712 | 2784 | 2227 | 1856 | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| ALUMINIMO | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818 | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Li-drill tsa HSS ke eng?

Li-drill tsa HSS ke liboro tsa tšepe tse khetholloang ka menyetla ea tsona ea ts'ebeliso ea bokahohle. Haholo-holo lihlahisoa tsa lihlopha tse nyenyane le tse mahareng, maemong a sa tsitsang a mechine le neng kapa neng ha ho hlokahala hore ho be thata, basebelisi ba ntse ba itšetlehile ka lisebelisoa tsa ho cheka tsa tšepe e phahameng (HSS/HSCO).

Liphapang tsa li-drill tsa HSS

Litšepe tse lebelo le phahameng li arotsoe ka maemo a fapaneng a boleng ho latela boima le boima. Likarolo tsa alloy tse kang tungsten, molybdenum le cobalt li ikarabella bakeng sa thepa ena. Ho eketseha ha likarolo tsa alloy ho eketsa ho hanyetsa mocheso, ho hanyetsa ho apara le ho sebetsa ha sesebelisoa, hammoho le theko ea theko. Ke ka lebaka leo ho leng bohlokoa ho nahana ka hore na ke likoti tse kae tse lokelang ho etsoa ka thepa efe ha u khetha thepa ea ho itšeha. Bakeng sa palo e nyane ea likoti, ho khothaletsoa thepa ea ho itšeha e theko e boima ka ho fetisisa ea HSS. Lisebelisoa tsa boleng bo holimo tse kang HSCO, M42 kapa HSS-E-PM li lokela ho khethoa bakeng sa tlhahiso ea letoto.

| Sehlopha sa HSS | HSS | HSCO(hape HSS-E) | M42(le HSCO8) | PM HSS-E |

| Tlhaloso | Litšepe tse tloaelehileng tsa lebelo le phahameng | Cobalt alloyed high speed steel | 8% cobalt alloyed high speed tšepe | Powder metallurgically hlahisa tšepe e phahameng ka potlako |

| Sebopeho | Max. 4.5% cobalt le 2.6% vanadium | Min. 4.5% cobalt kapa 2.6% vanadium | Min. 8% ea cobalt | Lisebelisoa tse tšoanang le HSCO, tlhahiso e fapaneng |

| Sebelisa | Tšebeliso e akaretsang | Sebelisa bakeng sa mocheso o phahameng oa ho itšeha / pholileng e sa rateheng, tšepe e sa hloekang | Sebelisa ka lisebelisoa tse thata ho seha | Sebelisa lihlahisoa tsa letoto le bakeng sa litlhoko tse phahameng tsa bophelo ba lisebelisoa |

Chate ea Khetho ea HSS Drill Bit

| LIPlasetiki | ALUMINIMO | KOPI | KOROPO | BOROPO | TŠEPILE KHABONE | NTS'EPE TŠEPE | TS'EPE E SA BENG LE MABALI | ||||

| MOEKETSI MANGATA | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| TS'EPE TŠEPE | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| TS'EPE MAEMO | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| TITANIUM e koetsoeng | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| TURBO TŠEPE | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSkaCOBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Chate ea Khetho ea Masonry Drill Bit

| LETSOPA SETENANE | TS'OANE SETENANE | B35 TŠENELE | B45 TŠENELE | RETS'ELISITSOE TS'ELISO | LEKANE | |

| StandardLITENANE | ✔ | ✔ | ||||

| Konkreite ea indasteri | ✔ | ✔ | ✔ | |||

| TURBO KONKERETE | ✔ | ✔ | ✔ | ✔ | ||

| SDS MOEKETSI | ✔ | ✔ | ✔ | |||

| SDS MOTSAMAI | ✔ | ✔ | ✔ | ✔ | ||

| SDS MOKHOA | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| MOEKETSI MANGATA | ✔ |

|

|

|

|