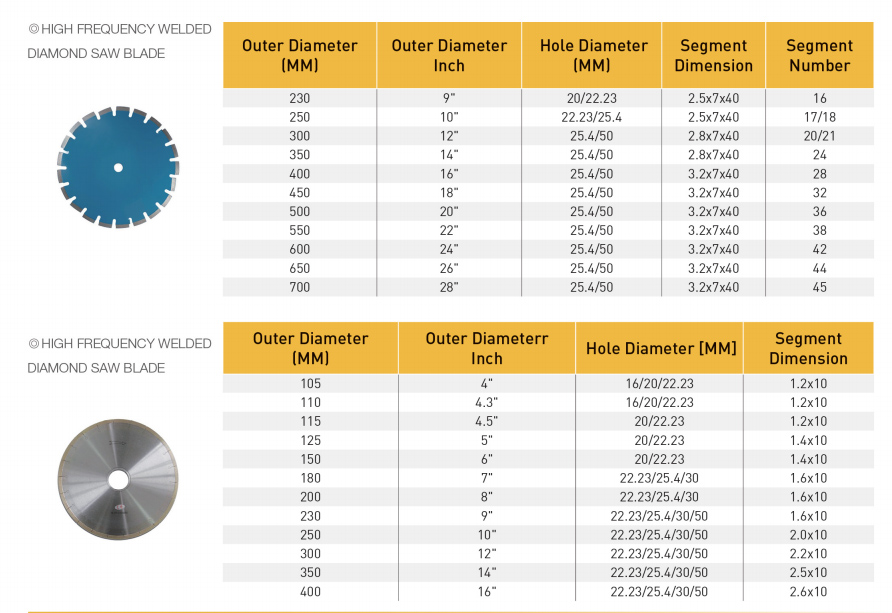

High Frequency Welded Diamond Saw Blade

Boholo ba Sehlahisoa

Tlhaloso ea Sehlahisoa

•Li-blades tsa daemane li ntle bakeng sa ho seha ka kakaretso lisebelisoa tse thata. Li tsitsitse 'me li na le lekhalo le moqotetsane la ho itšeha, kahoo li fokotsa litšila tsa majoe. Li lumella ho khaola ka potlako, mahala le ho boreleli. Ka lebaka la lebelo la ho itšeha ka potlako le ts'ebetso e phahameng, e ka khaola ka potlako lisebelisoa tse fapaneng tse thata. Sebaka sa ho itšeha se bataletse, se boreleli ebile se ts'oana, se netefatsa ho itšeha ka mokhoa o phahameng. Mocheso o fokolang haholo o hlahisoa nakong ea ho itšeha, kahoo o fokotsa likhohlano nakong ea ho itšeha, ho ntlafatsa ho bata ha letlapa, le ho boloka matla.

•Lisebelisoa tsa daemane li ka sebelisoa ka makhetlo a mangata 'me li na le nako e telele ea tšebeletso, ho fokotsa palo ea ho nkela sebaka le ho eketsa tlhahiso. Ntle le li-blocks tsa ho seha le ho lokisa, konkreite, thepa ea ho betla, litene, 'mabole, granite, lithaelese tsa ceramic le lisebelisoa tse ling tse thata, lisebelisoa tsa daemane le tsona li sebelisoa haholo. Mesebetsi ea ho seha le ho sebetsa ka mechine e ka etsoa ka lisebelisoa tse thata le tse matla tsa taemane. Ntle le ho fokotsa likhohlano le ho ntlafatsa ho hlaka ha slab, lisebelisoa tsa daemane li na le nako e telele ea tšebeletso 'me li ka sebelisoa hape ka makhetlo a mangata, ho fokotsa palo ea ho nkela sebaka le ho ntlafatsa tlhahiso. Ts'ebetso ea ho itšeha ea lisebelisoa tsa daemane e potlakile ebile e ka ntlafatsa ts'ebetso ea ts'ebetso.