Maxay yihiinQalloocinta Drills?

Maroojintu waa erey guud oo loo adeegsado noocyada kala duwan ee laylisyada, sida biraha, laylinta caaga ah, alwaaxyada, layliyada caalamiga ah, dhogorta dhuuban iyo kuwa shubka ah. Dhammaan laylisyada qalloocan waxay leeyihiin sifo guud: Fuufiyeyaasha helical ee bixiya magacooda. Qalloocyo kala duwan ayaa la adeegsadaa iyadoo ku xiran tahay adkaanta walxaha la doonayo in lagu farsameeyo.

Xagasha helix

Nooca N

●Ku haboon alaabta caadiga ah sida birta shubka.

●Nooca goynta goynta N waa wax badan oo ay ugu wacan tahay xagasha qalloocan ee ku dhawaad. 30°

Xagasha bar ee noocaan ah waa 118°.

Nooca H

●Ku habboon alaabta adag iyo kuwa jilicsan sida naxaasta.

●Xagasha helix-ga nooca H waxa ay ku dhowdahay 15°, taas oo keenta xagal weyn oo jeex ah oo leh cidhif yar oo fiiqan laakiin aad u deggan.

●Nooca H wuxuu kaloo leeyahay xagal bar ah 118°.

Nooca W

●Waxaa loo isticmaalaa alaabta jilicsan sida aluminium.

●Xagasha helix ee qiyaastii. 40° waxay keentaa xagal yar oo xagal goyn ah oo fiiqan laakiin marka la barbar dhigo aan deganayn.

●Xagasha barku waa 130°.

Maaddad ahaan

Xawaaraha Sare ee Birta (HSS)

Maaddada waxaa loo qaybin karaa qiyaas ahaan saddex nooc: bir xawaaraheeda sare leh, bir-xawaaraha sare leh oo kobalt ka kooban iyo carbide adag.

Laga soo bilaabo 1910-kii, birta xawaaraha sare leh ayaa loo isticmaali jiray qalab goynta in ka badan qarni. Hadda waa agabka ugu isticmaalka badan uguna jaban ee qalabka wax lagu gooyo. Dhaleeceynta birta xawaaraha sare leh waxaa loo isticmaali karaa labadaba farsamada gacanta iyo jawi xasiloon sida mashiinka qodista. Sababta kale ee sababta birta xawaarihiisu sarreeyo ay u socoto wakhti dheer ayaa laga yaabaa inay tahay sababtoo ah qalabka goynta birta xawaaraha sare leh ayaa dib loo dhigi karaa si isdaba joog ah. Sababtoo ah qiimihiisu yar yahay, looma isticmaalo oo keliya togrind drillbits, laakiin sidoo kale si ballaaran ayaa loo isticmaalaa qalabka leexinta.

Birta Xawaaraha Sare leh ee Cobalt-ka kooban (HSSE)

Cobalt-ka ku jira birta xawaaraha sare leh ayaa ka adag engegan iyo adayg guduudan oo ka wanaagsan birta xawaaraha sare leh. Korodhka adkaanta ayaa sidoo kale wanaajisa caabbinta xirashada, laakiin isla mar ahaantaana waxay bixisaa qayb ka mid ah adaygeeda. La mid ah birta xawaaraha sare leh: waxaa loo isticmaali karaa in lagu kordhiyo tirada jeer iyada oo la shiidi karo.

Carbide (CARBIDE)

Cementcarbide waa walxo isku jira oo bir ku salaysan. Waxaa ka mid ah, tungsten carbide waxaa loo isticmaalaa sida shaxanka, iyo qaar ka mid ah agabyada kale ayaa loo isticmaalaa sidii kuwa isku xira si ay u riixaan isostatic kulul iyo taxane taxane ah oo adag. Marka la barbardhigo birta xawaaraha sare leh marka la eego adayga, adayga cas iyo xidhashada caabbinta, si weyn ayaa loo hagaajiyay. Laakiin qiimaha qalabka goynta carbide sibidhka ayaa sidoo kale aad uga qaalisan birta xawaaraha sare leh. Carbid sibidhku wuxuu leeyahay faa'iidooyin badan marka loo eego qalabkii hore ee nolosha qalabka iyo xawaaraha farsamaynta. Qalabka shiida ee soo noqnoqda, qalabka wax lagu shiido xirfadlayaasha ayaa loo baahan yahay.

Dahaarka

Dahaar la'aan

Dahaarka waxa loo qaybin karaa qiyaas ahaan shanta nooc ee soo socota iyadoo loo eegayo baaxadda isticmaalka:

Qalabka aan la daboolin ayaa ah kuwa ugu raqiisan waxaana badanaa loo isticmaalaa in lagu farsameeyo qaar ka mid ah qalabka jilicsan sida aluminium aluminium iyo birta kaarboon yar.

Dahaarka Okssaydhka Madow

Dahaarka Oxide waxay ku siin karaan saliid ka wanaagsan qalabka aan la daboolin, sidoo kale waxay ku fiican yihiin oksaydhka iyo caabbinta kulaylka, waxayna kordhin karaan nolosha adeegga in ka badan 50%.

Titanium Nitride Coating

Titanium nitride waa sheyga ugu badan ee daahan, kumana habboona agabka adkeysigiisu aad u sarreeyo iyo heerkul sare.

Titanium Carbonitride Dahaarka

Titanium carbonitride waxaa laga soo saaray titanium nitride, waxay leedahay iska caabin heerkul sare oo sarreeya waxayna xidhataa caabbinta, badanaa guduud ama buluug. Waxaa loo adeegsaday aqoon-is-weydaarsiga Haas in lagu mariyo qalabyada shaqada ee ka samaysan birta shubka ah.

Titanium Aluminium Nitride Dahaarka

Titanium aluminium nitride aad ayey ugu adkeysi badan tahay heerkulka sare marka loo eego dhammaan dahaarka kor ku xusan, sidaas darteed waxaa loo isticmaali karaa meelaha sare ee goynta. Tusaale ahaan, farsamaynta superalloys. Waxa kale oo ay ku habboon tahay habaynta birta iyo birta, laakiin sababtoo ah waxay ka kooban tahay walxaha aluminium, falcelinta kiimikaad ayaa dhici doona marka la farsameynayo aluminium, markaa iska ilaali qalabka wax lagu sameeyo ee aluminiumku ku jiro.

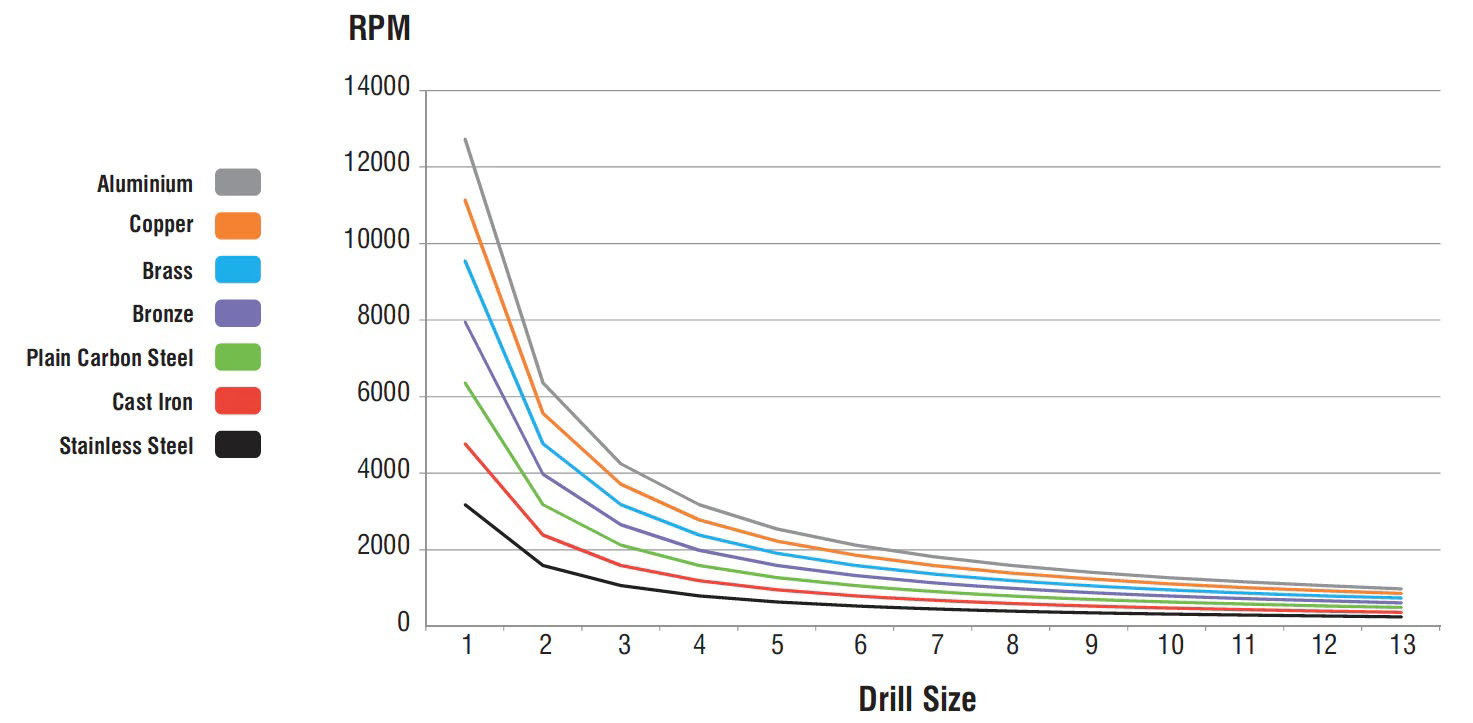

Xawaaraha qodista birta ee lagu taliyay

| Cabirka qodista | |||||||||||||

| 1MM | 2MM | 3MM | 4MM | 5MM | 6MM | 7MM | 8MM | 9MM | 10MM | 11MM | 12MM | 13MM | |

| AAN DHAQANBIRTA | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| KASTUURKA IRON | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| CADKAAROONBIRTA | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 | 795 | 707 | 636 | 579 | 530 | 490 |

| NAAR | 7955 | 3977 | 2652 | 1989kii | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| BRASS | 9545 | 4773 | 3182 | 2386 | 1909kii | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| NAxaas | 11136 | 5568 | 3712 | 2784 | 2227 | 1856kii | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| Aluminium | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818kii | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Waa maxay laylisyada HSS?

HSS-du waa laylisyo bir ah oo lagu garto suurtagalnimadooda codsi caalami ah. Gaar ahaan wax soo saarka taxane yar iyo mid dhexdhexaad ah, xaaladaha mashiinada aan xasilloonayn iyo mar kasta oo adag loo baahdo, isticmaalayaashu wali waxay ku tiirsan yihiin qalabka qodista birta xawaaraha sare leh (HSS/HSCO).

Farqiga u dhexeeya HSS

Birta xawaaraha sare leh waxay u qaybsantaa heerar kala duwan oo tayo leh iyadoo ku xidhan adkaanta iyo adkaanta. Qaybaha daawaha sida tungsten, molybdenum iyo cobalt ayaa ka mas'uul ah guryahan. Kordhinta qaybaha daawaynta waxay kordhisaa caabbinta xanaaqa, xidhashada caabbinta iyo waxqabadka qalabka, iyo sidoo kale qiimaha iibka. Tani waa sababta ay muhiim u tahay in la tixgeliyo inta godadka ah ee lagu samaynayo walxaha marka la dooranayo qalabka wax lagu gooyo. Tiro yar oo godad ah, waxa lagu talinayaa in la gooyo qalabka ugu qaalisan ee HSS. Qalabka goynta tayada sare leh sida HSCO, M42 ama HSS-E-PM waa in loo doortaa soo saarista taxane ah.

| heerka HSS | HSS | HSCO(sidoo kale HSS-E) | M42(sidoo kale HSCO8) | PM HSS-E |

| Sharaxaada | Bir-xawaaraha sare ee caadiga ah | Cobalt alloyed bir xawaaraha sare leh | 8% cobalt alloyed bir xawaaraha sare leh | Budada macdan ahaan waxay soo saartay bir xawaaraheeda sare leh |

| Halabuurka | Max. 4.5% cobalt iyo 2.6% vanadium | Min. 4.5% cobalt ama 2.6% vanadium | Min. 8% cobalt | Waxyaabaha la midka ah HSCO, wax soo saarka kala duwan |

| Isticmaal | Isticmaalka caalamiga ah | U isticmaal heerkulka goynta sare/ qaboojinta aan fiicnayn, birta aan fiicnayn | Ku isticmaal walxo ay adag tahay in la gooyo | U isticmaal wax soo saar taxane ah iyo shuruudaha nolosha aaladda sare |

Shaxda Xulashada Qodaafka HSS

| CAAGAYADA | Aluminium | NAxaas | BRASS | NAAR | BIRTA KAAROON CAD | KASTUURKA IRON | BIRTA AAN AHAYN | ||||

| UJEEDO BADAN | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| BIRTA WARSHADA | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| BIRTA STANDARD | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| TITANIUM oo dahaaran | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| BIRTA TURBO | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSlehCOBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Shaxda Xulashada Masonry Drill Bit

| BOQORKA Dhoobada | BUUG DAB AH | B35 CONCRETE | B45 CONCRETE | LA XOOJIYEY LAABKA | GANITE | |

| Heerkabulukeeti | ✔ | ✔ | ||||

| Lakabka Warshadaha | ✔ | ✔ | ✔ | |||

| TURBO CONCRETE | ✔ | ✔ | ✔ | ✔ | ||

| HEERKA SDS | ✔ | ✔ | ✔ | |||

| SDS warshadaha | ✔ | ✔ | ✔ | ✔ | ||

| SDS PROFESSIONAL | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| UJEEDO BADAN | ✔ |

|

|

|

|