ChiiTwist Drills?

Twist drill ishoko rekare remhando dzakasiyana-siyana dzezvibooresa, zvakaita sezvibooreso zvesimbi, zvibooreso zvepurasitiki, zvibooreso zvehuni, zvibooreso zvepasi rose, masonry nekongiri. Madhiri ese anomonereka ane hunhu hwakafanana: Nyere dzehelical dzinopa madhiri zita rawo. Different twist drills anoshandiswa zvichienderana nekuoma kwezvinhu zvichagadzirwa.

By helix angle

Type N

●Inokodzera zvinhu zvakajairika sesimbi yakakandwa.

●Mhando yeN yekucheka wedge inosiyana-siyana nekuda kweiyo twist angle ye approx. 30°.

Nzvimbo yekona yemhando iyi ndeye 118 °.

Type H

●Yakanakira zvinhu zvakaoma uye brittle zvakaita sebronze.

●Rudzi rweH helix angle yakatenderedza 15°, izvo zvinoita kuti pave nekona hombe yeweji ine kucheka kushoma asi kwakagadzikana zvakanyanya.

●Type H madrills anewo point angle ye118°.

Type W

●Inoshandiswa pazvinhu zvakapfava sealuminium.

●Iyo helix angle ye approx. 40° inoguma nekakona kadiki keweji kune yakapinza asi isina kugadzikana yekucheka.

●Nzvimbo yekona ndeye 130 °.

Nezvinhu

High Speed Steel (HSS)

Zvinhu zvacho zvinogona kukamurwa kuita mhando nhatu: simbi yekumhanya, cobalt-ine simbi yekumhanya uye yakasimba carbide.

Kubva 1910, high-speed simbi yakashandiswa sechinhu chekucheka kweanopfuura zana remakore. Parizvino ndiyo inonyanya kushandiswa uye yakachipa zvinhu zvekucheka maturusi. Yepamusoro-inomhanya simbi yekudhirowa inogona kushandiswa mune ese ari maviri madhiri uye amore yakagadzikana nharaunda senge muchina wekuchera. Chimwe chikonzero nei simbi yepamusoro inogara kwenguva yakareba inogona kunge iri yekuti maturusi ekucheka simbi anogona kudzokororwa kakawanda. Nekuda kwemutengo wayo wakaderera, haingoshandiswe chete kugaya zvibooresa, asi zvakare inoshandiswa zvakanyanya mukushandura maturusi.

Cobalt-ine High-Speed Steel (HSSE)

Cobalt-ine high-speed simbi ine kuoma kuri nani uye kuoma kwakatsvuka kupfuura simbi yakakwirira. Kuwedzera kwekuoma kunonatsiridza kusapfeka kwayo, asi panguva imwechete inobayira chikamu chekuoma kwayo. Zvakafanana nesimbi yepamusoro-soro: inogona kushandiswa kuwedzera nhamba yenguva kuburikidza nekukuya.

Carbide (CARBIDE)

Cementcarbide isimbi-based composite zvinhu. Pakati pavo, tungsten carbide inoshandiswa seye matrix, uye zvimwe zvimwe zvinhu zvinoshandiswa sezvisungo zve sinter nekupisa isostatic kudzvanya uye nhevedzano yemaitiro akaomarara. Kuenzaniswa nesimbi yepamusoro-soro maererano nekuoma, kuoma kwakatsvuka uye kupfeka kusagadzikana, yakagadziridzwa zvikuru. Asi mutengo wesimende yekucheka maturusi ekucheka zvakare unodhura zvakanyanya pane yakakwirira-kumhanya simbi. Cemented carbide ine mabhenefiti akawanda kupfuura ekare maturusi emidziyo maererano nehupenyu hwematurusi uye kumhanya kwekugadzirisa. Mukudzokororwa kwezvishandiso, maturusi ekukuya anodiwa anodiwa.

Nekupfekedza

Uncoated

Coatings inogona kukamurwa zvakaganhurwa mumhando shanu dzinotevera zvichienderana nehukuru hwekushandisa:

Zvishandiso zvisina kuvharwa ndizvo zvakachipa uye zvinowanzo shandiswa kugadzira zvimwe zvinhu zvakapfava zvakaita sealuminium alloy uye low carbon steel.

Black Oxide Coating

Oxide coatings inogona kupa lubricity iri nani pane maturusi asina kuvharwa, zvakare ari nani muoxidation uye kupisa kupisa, uye anogona kuwedzera hupenyu hwesevhisi neinopfuura 50%.

Titanium Nitride Coating

Titanium nitride ndiyo inonyanya kuvharisa zvinhu, uye haikodzeri zvinhu zvine hurema hwakanyanya uye nepamusoro pekugadzirisa tembiricha.

Titanium Carbonitride Coating

Titanium carbonitride inogadzirwa kubva kune titanium nitride, ine yakakwirira yepamusoro tembiricha kuramba uye kupfeka kuramba, kazhinji yepepuru kana yebhuruu. Inoshandiswa mumusangano weHaas kumichina yekushanda yakagadzirwa nesimbi yakakandwa.

Titanium Aluminium Nitride Coating

Titanium aluminium nitride inonyanya kupikisa kutonhora kwepamusoro kupfuura zvese zviri pamusoro apa, saka inogona kushandiswa munzvimbo dzakakwirira dzekucheka. Somuenzaniso, kugadzirisa superalloys. Inokodzerawo kugadzirwa kwesimbi uye simbi isina tsvina, asi nekuti ine aluminium zvinhu, kemikari inoitika kana ichigadzira aluminium, saka dzivisa zvinhu zvekugadzira zvine aluminium.

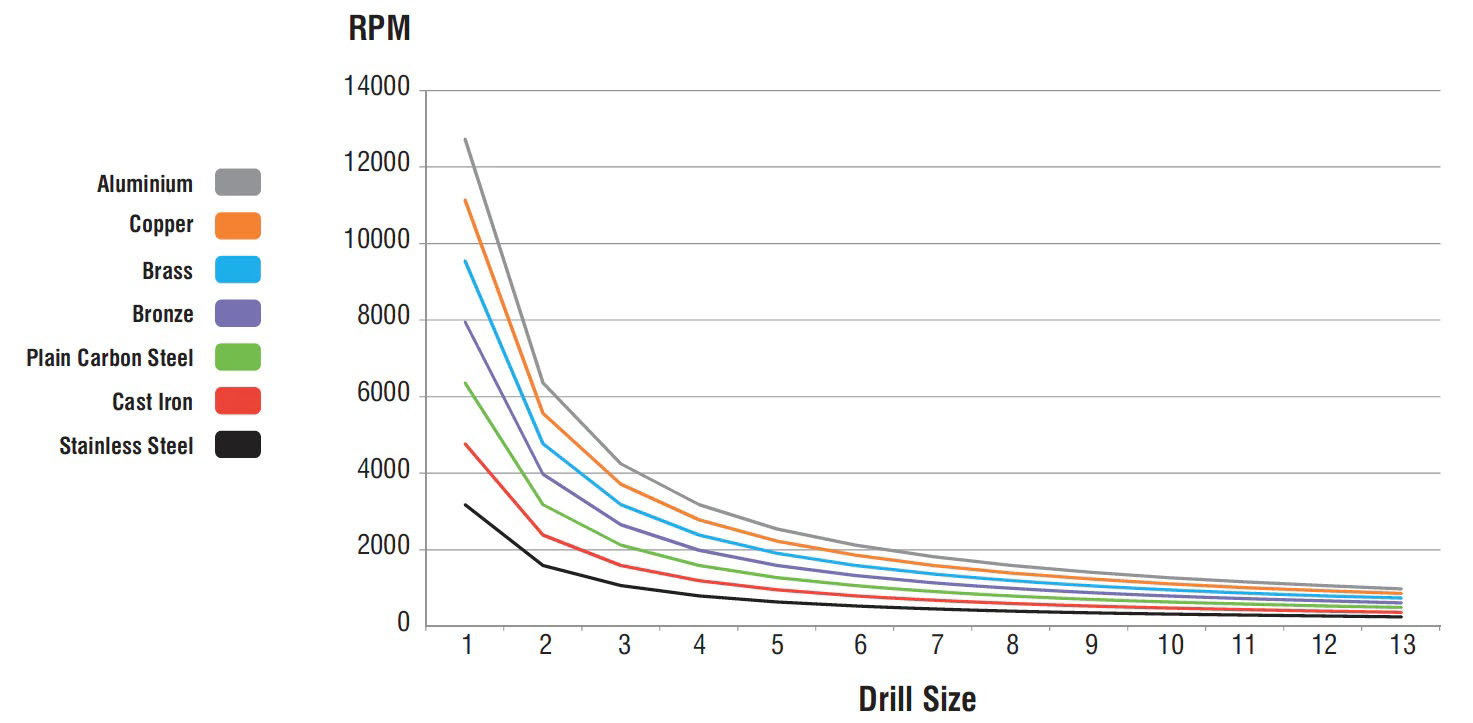

Inokurudzirwa Drilling Speeds In Metal

| Drill Size | |||||||||||||

| 1MM | 2MM | 3MM | 4MM | 5MM | 6MM | 7MM | 8MM | 9MM | 10MM | 11MM | 12MM | 13MM | |

| StainlessSIMBA | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| KANDA SIMBA | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| PLAINCARBONSIMBA | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 | 795 | 707 | 636 | 579 | 530 | 490 |

| BRONZE | 7955 | 3977 | 2652 | 1989 | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| BHASS | 9545 | 4773 | 3182 | 2386 | 1909 | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| Mhangura | 11136 | 5568 | 3712 | 2784 | 2227 | 1856 | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| ALUMINIUM | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818 | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Chii chinonzi HSS drills?

HSS drills zvibooreso zvesimbi izvo zvinoratidzirwa neavo epasi rose yekushandisa mikana. Kunyanya mumadiki uye epakati akatevedzana kugadzirwa, mumamiriro asina kugadzikana emuchina uye pese painoda kuomarara, vashandisi vachiri kuvimba nesimbi inomhanya kwazvo (HSS/HSCO) yekuchera maturusi.

Kusiyana muHSS drills

Simbi yepamusoro-soro yakakamurwa kuita nhanho dzemhando dzakasiyana zvichienderana nekuoma uye kuoma. Alloy zvikamu zvakaita se tungsten, molybdenum uye cobalt ndizvo zvinokonzeresa zvivakwa izvi. Kuwedzera alloy components kunowedzera kutsamwa kupikisa, kupfeka kuramba uye kushanda kwechishandiso, pamwe chete nemutengo wekutenga. Ichi ndicho chikonzero zvakakosha kufunga kuti makomba mangani anofanira kuitwa mune zvinyorwa pakusarudza zvinhu zvekucheka. Kune mashoma mashoma maburi, iyo inonyanya kudhura-inoshanda yekucheka zvinhu HSS inokurudzirwa. Yepamusoro-mhando yekucheka zvinhu senge HSCO, M42 kana HSS-E-PM inofanirwa kusarudzirwa kugadzirwa kwakatevedzana.

| HSS giredhi | HSS | HSCO(zvakare HSS-E) | M42(zvakare HSCO8) | PM HSS-E |

| Tsanangudzo | Yakajairika high-speed simbi | Cobalt alloyed high speed simbi | 8% cobalt alloyed high speed simbi | Powder metallurgically yakagadzirwa nesimbi yakakwirira-kumhanya |

| Composition | Max. 4.5% cobalt uye 2.6% vanadium | Min. 4.5% cobalt kana 2.6% vanadium | Min. 8% cobalt | Zvakafanana zvinongedzo seHSCO, kugadzirwa kwakasiyana |

| Shandisa | Kushandiswa kwese | Shandisa kune yakakwirira yekucheka tembiricha / kutonhora kusingafadzi, simbi isina tsvina | Shandisa nezvinhu zvakaoma-kucheka | Shandisa mukutevedzana kugadzira uye kune yakakwirira maturusi ehupenyu zvinodiwa |

HSS Drill Bit Sarudzo Chati

| PLASTICS | ALUMINIUM | Mhangura | BHASS | BRONZE | PLAIN CARBON STEEL | KANDA SIMBA | SIMBI ISINA NGURA | ||||

| MULTI-CHINANGWA | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| INDUSTRIAL METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| STANDARD METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| TITANIUM yakavharwa | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Nhoroondo ye TURBO METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSpamweCOBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Masonry Drill Bit Selection Chati

| CLAY BRICK | ZVITINHU CHEMOTO | B35 KONCRETE | B45 KONCRETE | KUSIMBISA KONCRETE | GRANITE | |

| StandardBRICK | ✔ | ✔ | ||||

| Industrial Concrete | ✔ | ✔ | ✔ | |||

| TURBO CONCRETE | ✔ | ✔ | ✔ | ✔ | ||

| SDS STANDARD | ✔ | ✔ | ✔ | |||

| SDS INDUSTRIAL | ✔ | ✔ | ✔ | ✔ | ||

| SDS PROFESSIONAL | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| MULTI-CHINANGWA | ✔ |

|

|

|

|