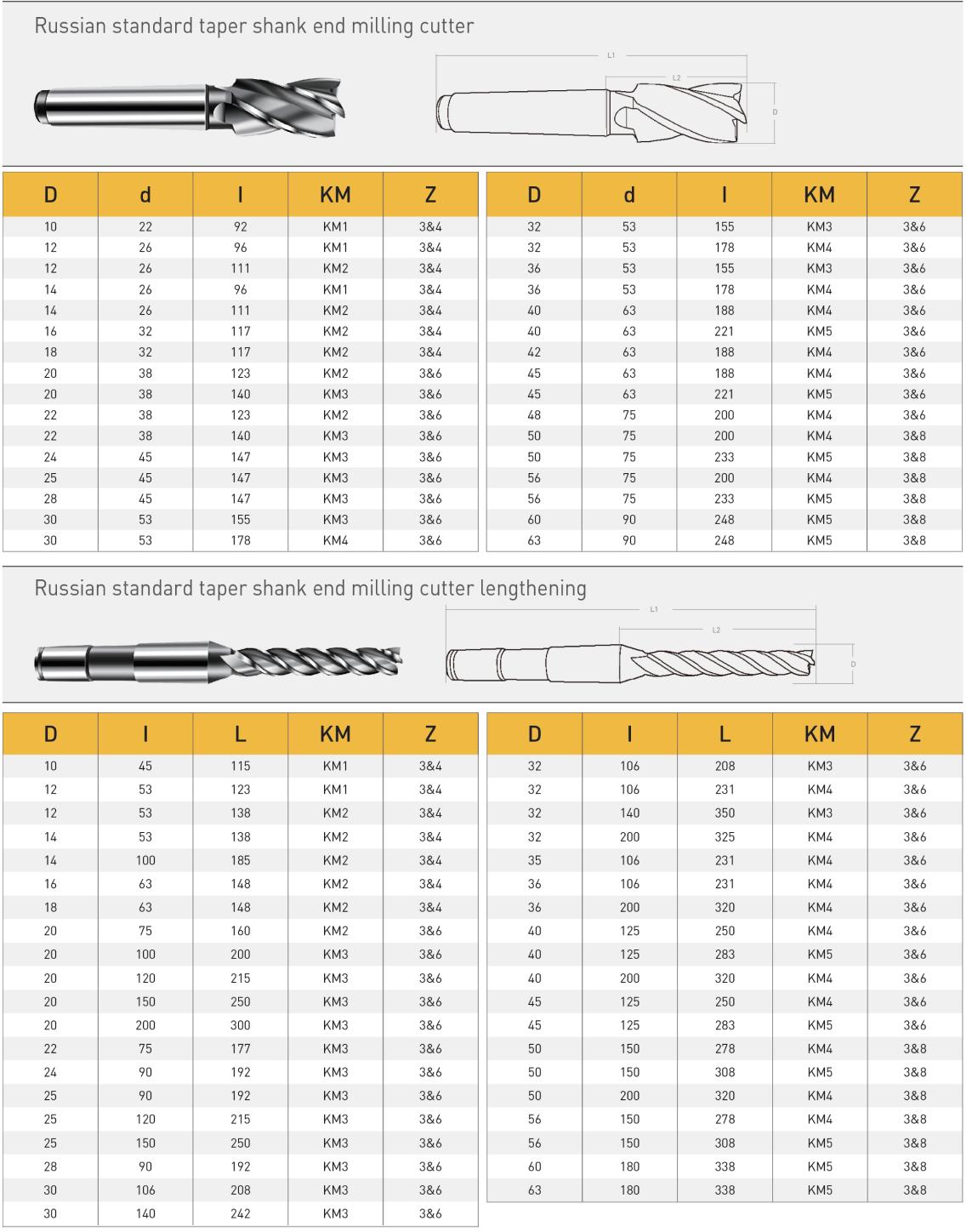

Russian Standard Taper Shank End Milling Cutter

Product Size

Product Description

A knife's wear resistance depends on the materials, the heat treatment process, and the grinding technology of the tool. In addition, Eurocut milling cutters provide outstanding performance in daily use while exhibiting impressive durability during continuous, high-intensity operations. Due to its long service life, professional users are able to use it for the rest of their lives because it has such a long service life.

During precision machining, Eurocut milling cutters ensure accurate workpieces by ensuring micron-level precision. In order to ensure consistency and quality of cutting during high-speed operation, good cutting stability means the tool is less likely to vibrate. Eurocut milling cutters are precisely controlled down to the nanometer. By integrating modern CNC machine tools with our milling cutters, processing efficiency will undoubtedly be improved and final quality will be improved.

A milling cutter must be strong enough to resist impacts during the cutting process so that it does not break easily when used as a cutting tool. Erurocut milling cutters are strong and tough, as well as extremely durable. Milling cutters must be extremely durable to prevent chipping and chipping problems since they will be impacted and vibrated during the cutting process. There are certain properties that need to be present in a cutting tool for it to remain stable and reliable under a variety of cutting conditions, especially when the cutting conditions are complex and constantly changing.