Ndi chiyaniKupotoza Drills?

Twist drill ndi liwu lodziwika bwino la zobowola zamitundu yosiyanasiyana, monga zobowola zitsulo, zobowola pulasitiki, zobowola matabwa, zobowola zapadziko lonse lapansi, zobowola zamatabwa ndi konkriti. Zobowola zonse zimakhala ndi mawonekedwe ofanana: Zitoliro za helical zomwe zimapatsa zidazo dzina lawo. Zobowola zosiyanasiyana zimagwiritsidwa ntchito kutengera kuuma kwa zinthu zomwe zimapangidwira.

Pa ngodya ya helix

Mtundu N

●Oyenera zinthu zabwinobwino monga chitsulo choponyedwa.

●Mtundu wa N cutting wedge umakhala wosunthika chifukwa cha kupindika kwake pafupifupi. 30 °.

Mbali yamtundu uwu ndi 118 °.

Mtundu H

●Zabwino pazida zolimba komanso zowonongeka monga bronze.

●Mtundu wa H helix ngodya ndi yozungulira 15 °, zomwe zimapangitsa kuti pakhale ngodya yayikulu yocheperako koma yokhazikika kwambiri.

●Zobowola zamtundu wa H zilinso ndi ngodya ya 118 °.

Mtundu W

●Amagwiritsidwa ntchito pazinthu zofewa monga aluminium.

●Ngongole ya helix pafupifupi. 40° imapangitsa kuti pakhale kapendeke kakang'ono kuti pakhale m'mphepete mwakuthwa koma wosakhazikika.

●Mbali ya nsonga ndi 130 °.

Mwa zinthu

High Speed Steel (HSS)

Zinthuzi zitha kugawidwa pafupifupi mitundu itatu: chitsulo chothamanga kwambiri, cobalt chokhala ndi chitsulo chothamanga kwambiri komanso carbide yolimba.

Kuyambira 1910, chitsulo chothamanga kwambiri chakhala chikugwiritsidwa ntchito ngati chida chodulira kwazaka zopitilira zana. Pakalipano ndizomwe zimagwiritsidwa ntchito kwambiri komanso zotsika mtengo kwambiri zodulira zida. Zobowola zitsulo zothamanga kwambiri zitha kugwiritsidwa ntchito pobowola manja komanso malo okhazikika monga makina obowola. Chifukwa china chomwe chitsulo chothamanga kwambiri chimakhala kwa nthawi yayitali chingakhale chifukwa zida zodulira zitsulo zothamanga kwambiri zimatha kubwerezedwa mobwerezabwereza. Chifukwa cha mtengo wake wotsika, sichimagwiritsidwa ntchito pogaya ma drillbits okha, komanso amagwiritsidwa ntchito kwambiri potembenuza zida.

Cobalt-Containing High-Speed Steel (HSSE)

Cobalt yokhala ndi chitsulo chothamanga kwambiri imakhala ndi kuuma bwino komanso kuuma kofiira kuposa chitsulo chothamanga kwambiri. Kuwonjezeka kwa kuuma kumathandizanso kukana kwake kuvala, koma nthawi yomweyo kumapereka gawo la kulimba kwake. Zomwezo ndi zitsulo zothamanga kwambiri: zingagwiritsidwe ntchito kuonjezera chiwerengero cha nthawi kupyolera mukupera.

Carbide (CARBIDE)

Cementcarbide ndi zitsulo zopangidwa ndi zitsulo. Mwa iwo, tungsten carbide imagwiritsidwa ntchito ngati matrix, ndipo zida zina zimagwiritsidwa ntchito ngati zomangira za sinter ndi kutentha kwa isostatic ndi njira zingapo zovuta. Poyerekeza ndi zitsulo zothamanga kwambiri ponena za kuuma, kuuma kofiira ndi kukana kuvala, zakhala zikuyenda bwino kwambiri. Koma mtengo wa zida zodulira simenti za carbide ndizokwera mtengo kwambiri kuposa chitsulo chothamanga kwambiri. Carbide yokhala ndi simenti ili ndi zabwino zambiri kuposa zida zam'mbuyomu potengera moyo wa zida komanso kuthamanga kwachangu. Pakugaya mobwerezabwereza kwa zida, zida zogaya akatswiri zimafunikira.

Pokutira

Osakutidwa

Zovala zimatha kugawidwa m'magulu asanu otsatirawa malinga ndi kuchuluka kwa ntchito:

Zida zopanda zokutira ndizotsika mtengo kwambiri ndipo nthawi zambiri zimagwiritsidwa ntchito popanga zida zofewa monga aluminium alloy ndi low carbon steel.

Kupaka kwa Black Oxide

Zopaka za okosijeni zimatha kupereka mafuta ochulukirapo kuposa zida zosavunditsidwa, zimakhalanso bwino ndi okosijeni komanso kukana kutentha, ndipo zimatha kuwonjezera moyo wautumiki ndi kupitilira 50%.

Kupaka kwa Titanium Nitride

Titaniyamu nitride ndiye ❖ kuyanika wamba zakuthupi, ndipo si oyenera zipangizo ndi kuuma kwambiri ndi mkulu processing kutentha.

Titanium Carbonitride Coating

Titaniyamu carbonitride amapangidwa kuchokera titaniyamu nitride, ali apamwamba kutentha kukana ndi kuvala kukana, kawirikawiri wofiirira kapena buluu. Amagwiritsidwa ntchito mumsonkhano wa Haas kupanga makina opangira zitsulo zopangidwa ndi chitsulo.

Titanium Aluminium Nitride Coating

Titanium aluminium nitride imalimbana ndi kutentha kwambiri kuposa zokutira zonse pamwambapa, kotero itha kugwiritsidwa ntchito m'malo odula kwambiri. Mwachitsanzo, kukonza superalloys. Ndiwoyeneranso kukonzanso zitsulo ndi zitsulo zosapanga dzimbiri, koma chifukwa zili ndi zinthu zotayidwa, zotsatira za mankhwala zidzachitika pokonza aluminium, choncho pewani zipangizo zopangira aluminium.

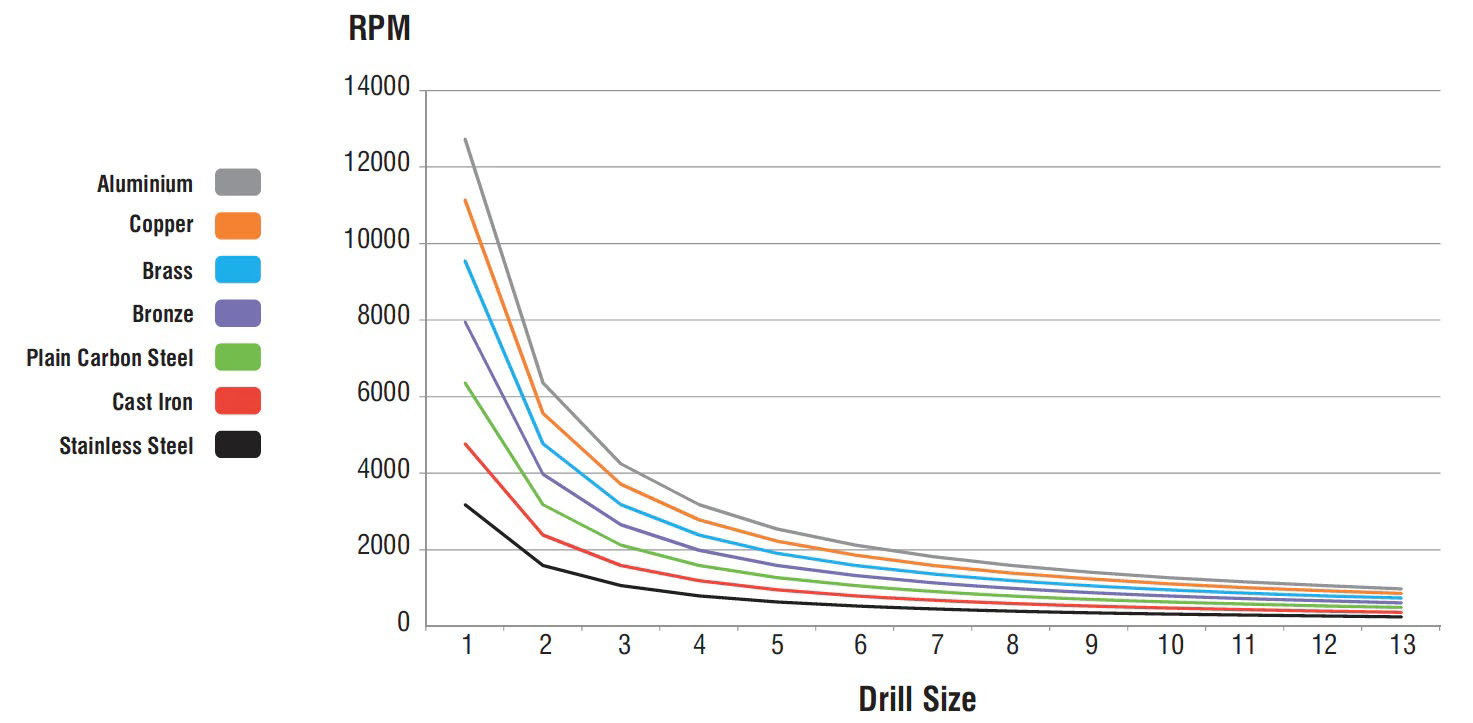

Analimbikitsa Kubowola Kuthamanga Mu Zitsulo

| Kubowola Kukula | |||||||||||||

| 1 MM | 2 MM | 3 MM | 4 MM | 5 MM | 6 MM | 7 MM | 8 MM | 9 mm | 10 mm | 11 MM | 12 MM | 13 MM | |

| ZOSAPANGACHIZINDIKIRO | 3182 | 1591 | 1061 | 795 | 636 | 530 | 455 | 398 | 354 | 318 | 289 | 265 | 245 |

| POLYANI chitsulo | 4773 | 2386 | 1591 | 1193 | 955 | 795 | 682 | 597 | 530 | 477 | 434 | 398 | 367 |

| ZABWINOKABONANICHIZINDIKIRO | 6364 | 3182 | 2121 | 1591 | 1273 | 1061 | 909 pa | 795 | 707 | 636 | 579 | 530 | 490 |

| BRONZE | 7955 | 3977 | 2652 | 1989 | 1591 | 1326 | 1136 | 994 | 884 | 795 | 723 | 663 | 612 |

| BRASI | 9545 | 4773 | 3182 | 2386 | 1909 | 1591 | 1364 | 1193 | 1061 | 955 | 868 | 795 | 734 |

| MCHWA | 11136 | 5568 | 3712 | 2784 | 2227 | 1856 | 1591 | 1392 | 1237 | 1114 | 1012 | 928 | 857 |

| ALUMINIMU | 12727 | 6364 | 4242 | 3182 | 2545 | 2121 | 1818 | 1591 | 1414 | 1273 | 1157 | 1061 | 979 |

Kodi ma HSS drills ndi chiyani?

Kubowola kwa HSS ndi zobowolera zitsulo zomwe zimadziwika ndi kuthekera kwawo konsekonse. Makamaka pamapangidwe ang'onoang'ono ndi apakatikati, m'mikhalidwe yosakhazikika ya makina komanso nthawi iliyonse ikafunika kulimba, ogwiritsa ntchito amadalirabe zida zobowola zitsulo zothamanga kwambiri (HSS/HSCO).

Kusiyana kwa ma drill a HSS

Chitsulo chothamanga kwambiri chimagawidwa m'magulu osiyanasiyana malinga ndi kuuma ndi kulimba. Zigawo za aloyi monga tungsten, molybdenum ndi cobalt ndizomwe zimayambitsa izi. Kuwonjezeka kwa zigawo za alloy kumawonjezera kukana kutentha, kukana kuvala ndi ntchito ya chida, komanso mtengo wogula. Ichi ndichifukwa chake ndikofunikira kulingalira za mabowo angati omwe angapangidwe muzinthu zomwe posankha zodula. Pamabowo ochepa, HSS yodula kwambiri ndiyofunikira. Zida zodulira zapamwamba kwambiri monga HSCO, M42 kapena HSS-E-PM ziyenera kusankhidwa kuti zipangidwe.

| Mtengo wa HSS | HSS | Mtengo wa HSCO(komanso HSS-E) | M42(komanso HSCO8) | PM HSS-E |

| Kufotokozera | Chitsulo chokhazikika chothamanga kwambiri | Cobalt alloyed high speed chitsulo | 8% cobalt alloyed mkulu liwiro chitsulo | Ufa metallurgically opangidwa mkulu-liwiro zitsulo |

| Kupanga | Max. 4.5% cobalt ndi 2.6% vanadium | Min. 4.5% cobalt kapena 2.6% vanadium | Min. 8% cobalt | Zosakaniza zofanana ndi HSCO, kupanga kosiyana |

| Gwiritsani ntchito | Kugwiritsa ntchito konsekonse | Gwiritsani ntchito kutentha kwambiri / kuzizira kosasangalatsa, chitsulo chosapanga dzimbiri | Gwiritsani ntchito ndi zipangizo zovuta kudula | Gwiritsani ntchito pakupanga mndandanda komanso zofunikira za moyo wa zida |

Tchati cha HSS Drill Bit Selection

| PLASTIKI | ALUMINIMU | MCHWA | BRASI | BRONZE | PLAIN CARBON zitsulo | POLYANI chitsulo | CHITSULO CHOSAPANGA DZIMBIRI | ||||

| ZOFUNIKA KWAMBIRI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| INDUSTRIAL METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| ZINTHU ZONSE | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

| |||

| TITANIUM yokutidwa | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Mtengo wa TURBO METAL | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| HSSndiCOBALT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

Masonry Drill Bit Selection Tchati

| NJErwa ZA DONGO | NJErwa ZAMOTO | B35 KONJITI | B45 KONJITA | KONJIRA YOLIMBIKITSA | GRANITE | |

| StandardNJEREWA | ✔ | ✔ | ||||

| Industrial Concrete | ✔ | ✔ | ✔ | |||

| TURBO CONCRETE | ✔ | ✔ | ✔ | ✔ | ||

| Mtengo wa SDS | ✔ | ✔ | ✔ | |||

| Malingaliro a kampani SDS INDUSTRIAL | ✔ | ✔ | ✔ | ✔ | ||

| Malingaliro a kampani SDS PROFESSIONAL | ✔ | ✔ | ✔ | ✔ | ✔ | |

| SDS REBAR | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zithunzi za SDS MAX | ✔ | ✔ | ✔ | ✔ | ✔ | |

| ZOFUNIKA KWAMBIRI | ✔ |

|

|

|

|