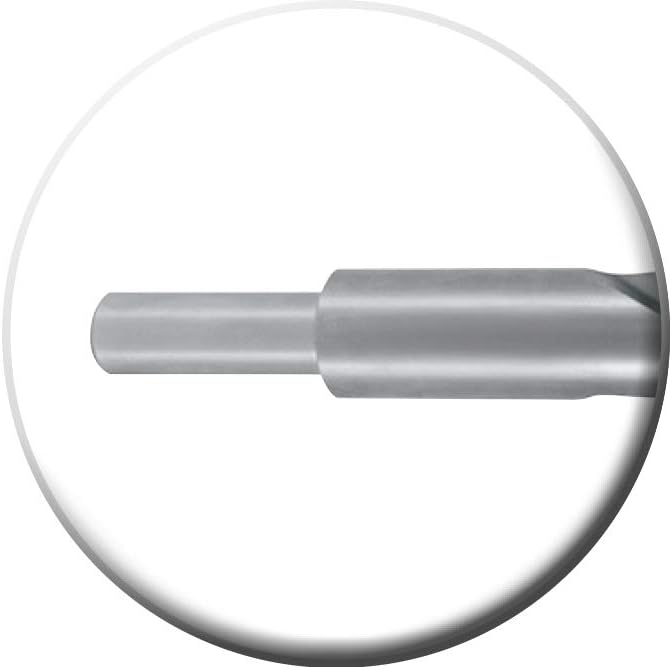

Din338 Suda HSS Drill Bit

Produk Show

| Bahan | 4241,4341, M2, M35, M42 |

| Standar | DIN 338 |

| Proses | Full Ground, Setengah lemah, Roll ground |

| Shank | Ngurangi latihan shank |

| gelar | 135 ° Split Point utawa 118 ° Pilot Point |

| lumahing | Amber, Ireng, Padhang, Ganda, Pelangi, Timah dilapisi |

| Panggunaan | |

| Stainless steel, Pengeboran Logam, Aluminium, PVC dll. | |

| Customized | OEM, ODM |

| Paket | 10/5 Pcs ing Kantong PVC, Kothak Plastik, Individu ing Kartu Kulit, Double Blister, Clamshell. |

Baja kacepetan dhuwur minangka bahan sing digunakake. Baja kacepetan dhuwur iki diolah kanthi panas supaya bisa nambah kekerasan, kekuatan tarik lan umur pemotongan sajrone wektu. Salajengipun, desain tip bor bit ora mung menehi stabilitas dhuwur lan tliti, nanging uga ketajaman lan karakteristik non-slip, kang siji ngluwihi umur layanan. Lading sing wis dipotong ngresiki pinggiran bolongan, nalika pandhuan mburi dual njamin akurasi sing dhuwur. Mata bor iku kaku, mula ora mlengkung kaya bor dawa.

Saliyane pinggiran chisel tapered standar, suling chip lan pinggiran mburi banget dibunderaké dirancang khusus kanggo pengeboran logam, asil ing pas, bolongan resik. Bor iki arang banget awet lan bisa adaptasi karo desain gagang suda sing pas lan ora gampang pecah. Saliyane nambah kinerja lan efisiensi, desain rotary nambah kecepatan pengeboran. Perawatan lumahing nyegah teyeng lan nyandhang. Yen sampeyan duwe bolongan ukuran tartamtu, pengeboran iki nyuda pasukan tikaman kanthi 50%, njamin bolongan bunder sing sampurna. Shank nyuda rotasi ing chuck, lan bit shank ditandhani kanggo identifikasi ukuran sing gampang.

Ukuran

| Dia | L2 | L1 | d | ||

| 10.5 | 87 | 133 | 10.0 | ||

| 11 | 94 | 142 | 10.0 | ||

| 11.5 | 94 | 142 | 10.0 | ||

| 12 | 101 | 151 | 10.0 | ||

| 12.5 | 101 | 151 | 10.0 | ||

| 13 | 101 | 151 | 10.0 | ||

| 13.5 | 108 | 160 | 10.0 | ||

| 13.5 | 108 | 160 | 13.0 | ||

| 14 | 108 | 160 | 10.0 | ||

| 14 | 108 | 160 | 13.0 | ||

| 14.5 | 114 | 169 | 10.0 | ||

| 14.5 | 114 | 169 | 13.0 | ||

| 15 | 114 | 169 | 10.0 | ||

| 15 | 114 | 169 | 13.0 | ||

| 15.5 | 120 | 178 | 10.0 | ||

| 10.5 | 87 | 133 | 10.0 | ||

| 11 | 94 | 142 | 10.0 | ||

| 11.5 | 94 | 142 | 10.0 | ||

| 12 | 101 | 151 | 10.0 | ||

| 12.5 | 101 | 151 | 10.0 | ||

| 13 | 101 | 151 | 10.0 | ||

| Dia | L2 | L1 | d | ||

| 13.5 | 108 | 160 | 10.0 | ||

| 13.5 | 108 | 160 | 13.0 | ||

| 14 | 108 | 160 | 10.0 | ||

| 14 | 108 | 160 | 13.0 | ||

| 14.5 | 114 | 169 | 10.0 | ||

| 14.5 | 114 | 169 | 13.0 | ||

| 15 | 114 | 169 | 10.0 | ||

| 15 | 114 | 169 | 13.0 | ||

| 15.5 | 120 | 178 | 10.0 | ||

| 15.5 | 120 | 178 | 13.0 | ||

| 16 | 120 | 178 | 10.0 | ||

| 16 | 120 | 178 | 13.0 | ||

| 16.5 | 125 | 184 | 10.0 | ||

| 16.5 | 125 | 184 | 13.0 | ||

| 17 | 125 | 184 | 10.0 | ||

| 17 | 125 | 184 | 13.0 | ||

| 17.5 | 130 | 191 | 13.0 | ||

| 18 | 130 | 191 | 10.0 | ||

| 18 | 130 | 191 | 13.0 | ||

| 18.5 | 135 | 198 | 13.0 | ||

| 19 | 135 | 198 | 13.0 | ||

| 19.5 | 140 | 205 | 13.0 | ||

| 20 | 140 | 205 | 10.0 | ||

| 20 | 140 | 205 | 13.0 | ||