DIN844 Standard End Mill Cutter

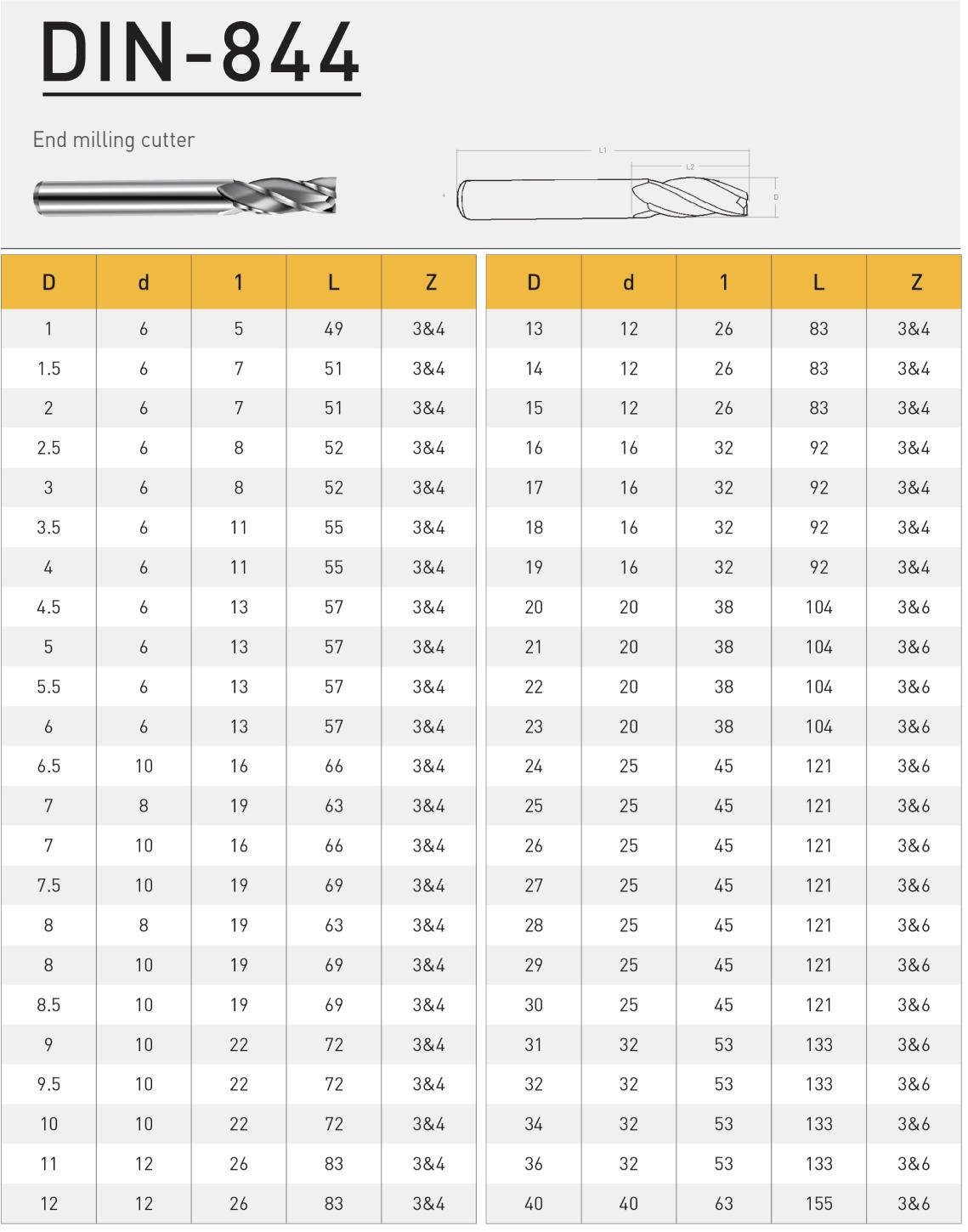

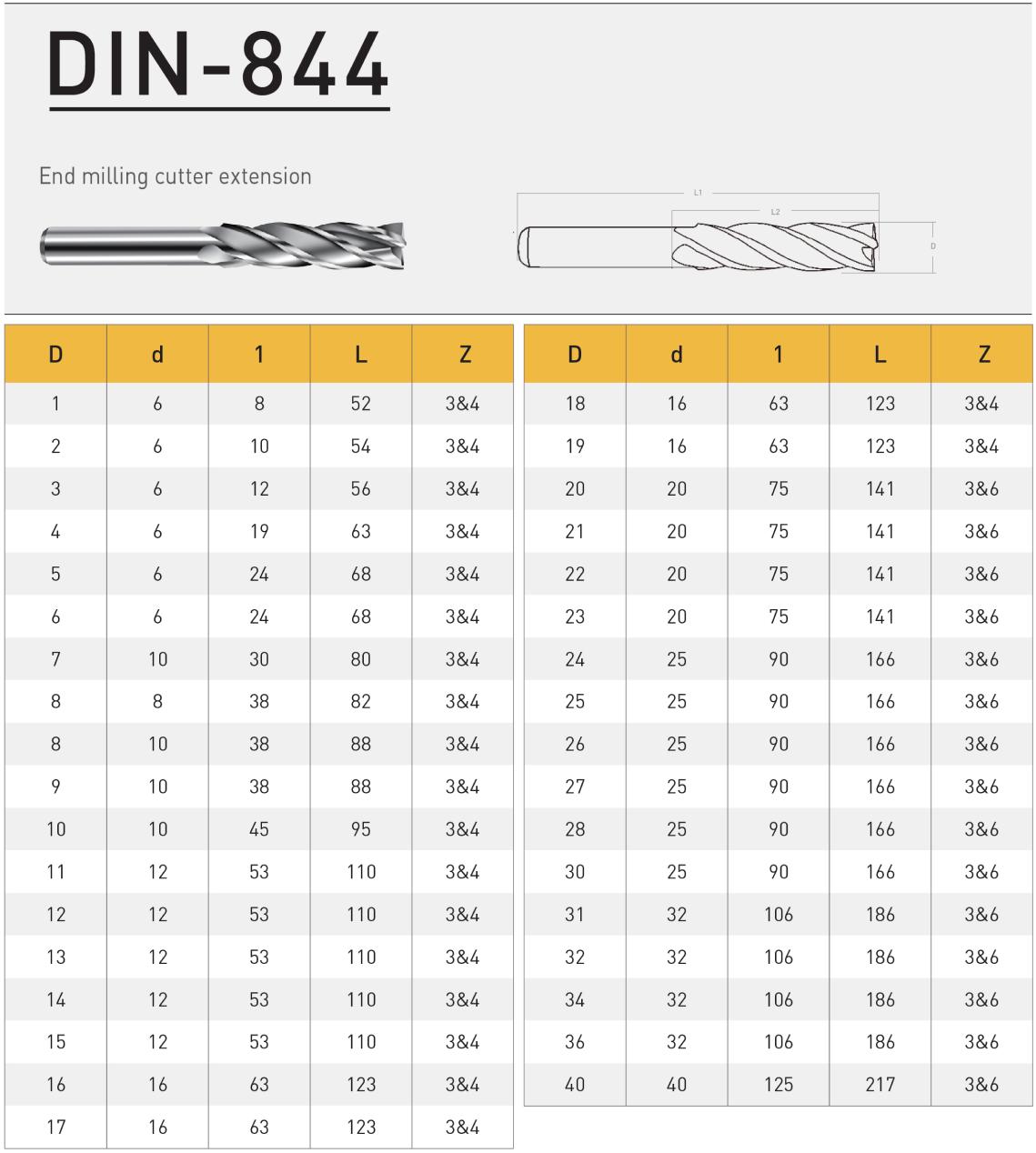

Product Size

Product Description

The wear resistance of a knife determines its ability to stay sharp with continued use. This is closely related to the material, heat treatment process and grinding technology of the tool. Eurocut milling cutters not only perform stable in daily use, but also show impressive durability in continuous high-intensity operations. Its service life is so long that it can even accompany some professional users throughout their lives.

In precision machining, the accuracy of the tool diameter directly affects the final quality of the workpiece. Eurocut high-precision milling cutters, whose diameter is controlled to the micron level, ensure accuracy. Good cutting stability means that the tool is less likely to vibrate during high-speed operation, ensuring cutting consistency and surface finish. When paired with advanced CNC machine tools, our milling cutters can undoubtedly greatly improve processing efficiency and product quality.

In addition, Erurocut milling cutters have a high level of strength and toughness. As a cutting tool, it needs to be able to withstand a lot of impact forces during the cutting process, so it needs to have a high level of strength, otherwise it will easily break and become damaged. In addition, because milling cutters will be impacted and vibrated during the cutting process, they should also be extremely tough in order to prevent chipping and chipping problems. In order to maintain stable and reliable cutting capabilities under complex and changeable cutting conditions, the cutting tool must have properties such as these.