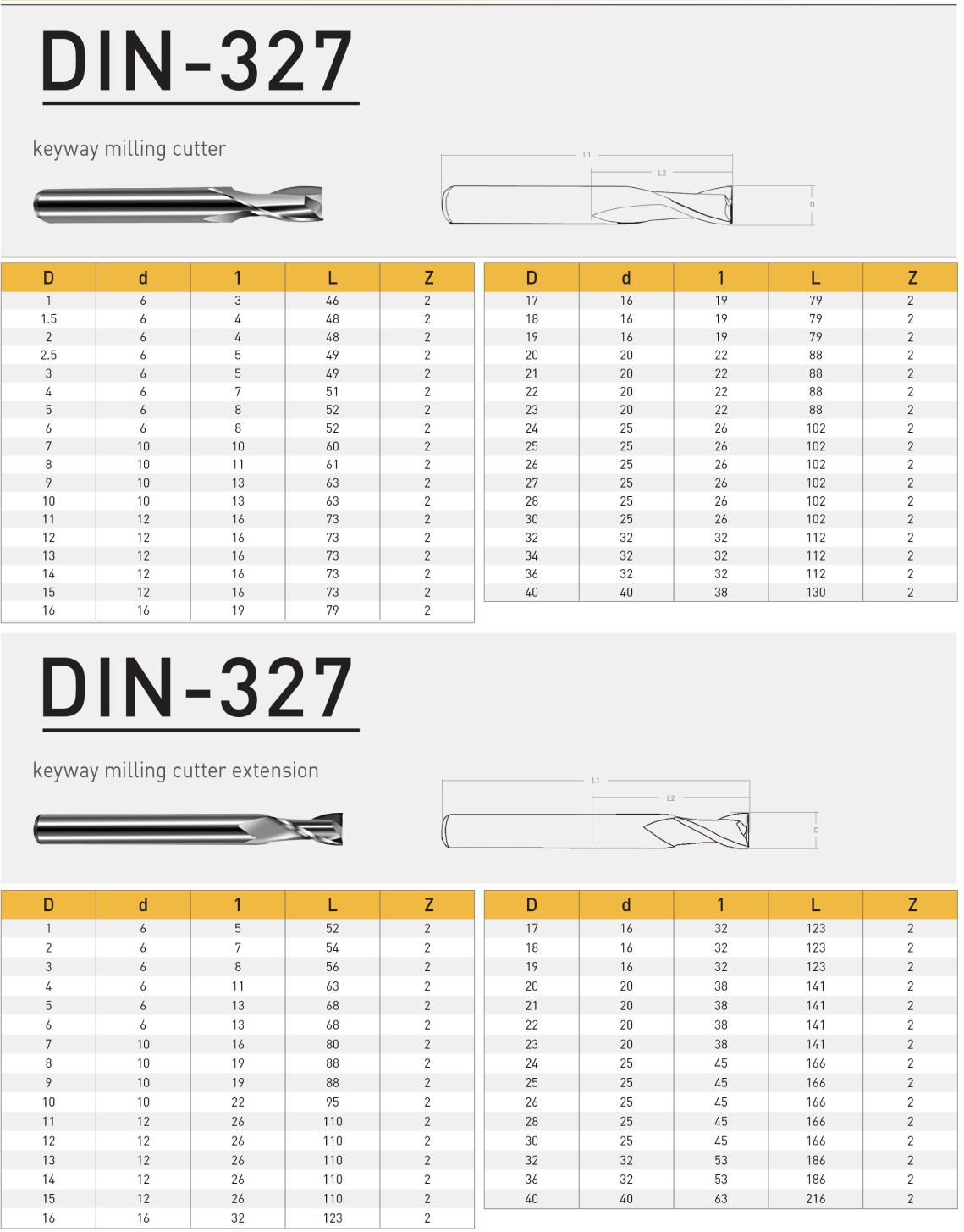

DIN327 Standard End Mill Cutter

Product Size

Product Description

At high cutting speeds, cutting generates a significant amount of heat, causing temperatures to spike rapidly as a consequence. In the absence of good heat resistance, a tool will lose its hardness at high temperatures, reducing its cutting efficiency. Our milling cutter materials remain hard even at high temperatures, allowing them to continue cutting regardless of high temperatures. This property is also known as thermohardness or red hardness. To prevent overheating from leading to tool failure under high temperatures and maintain stable cutting performance, heat-resistant cutting tools are required.

During the cutting process, the cutters must be able to withstand a lot of impact force, otherwise they will easily break. Erurocut milling cutters are not only strong and tough, but also tough. Since the milling cutter will be impacted and vibrated during the cutting process, it must also be tough to prevent chipping and chipping problems. It is only when cutting tools possess these characteristics that they will be able to perform consistently and reliably under changing and complex cutting conditions.

The installation and adjustment of a milling cutter should be followed by strict operating procedures to ensure that the cutter is in contact and angled correctly with the workpiece. By doing so, we will be able to improve processing efficiency and prevent equipment failure and workpiece damage because of improper adjustment.