American Standard End Milling Cutter

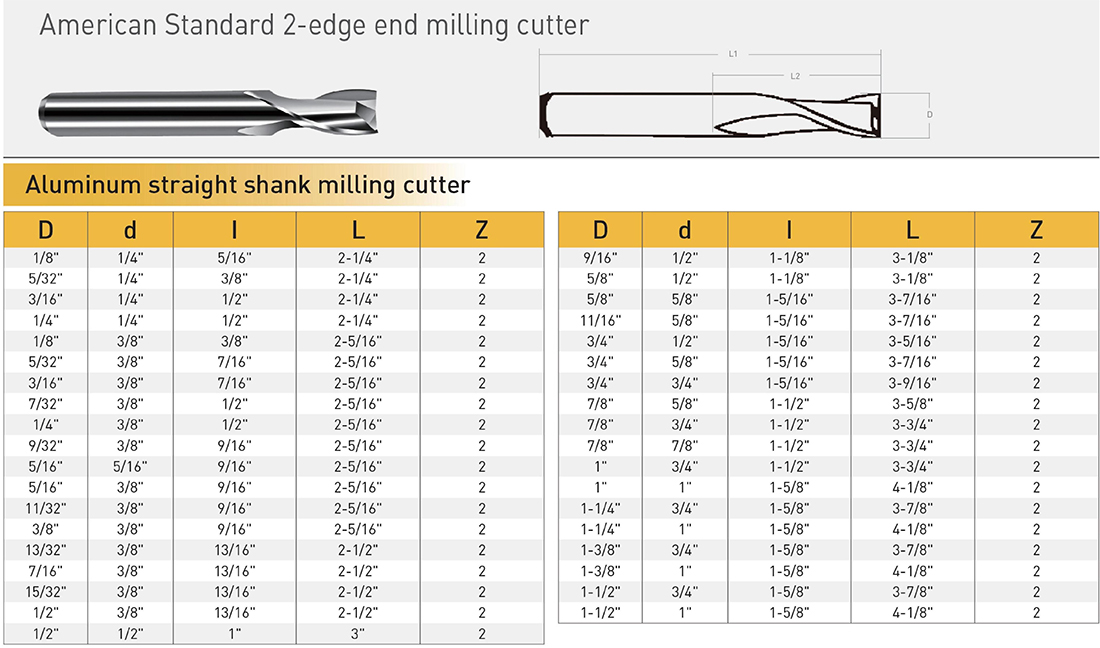

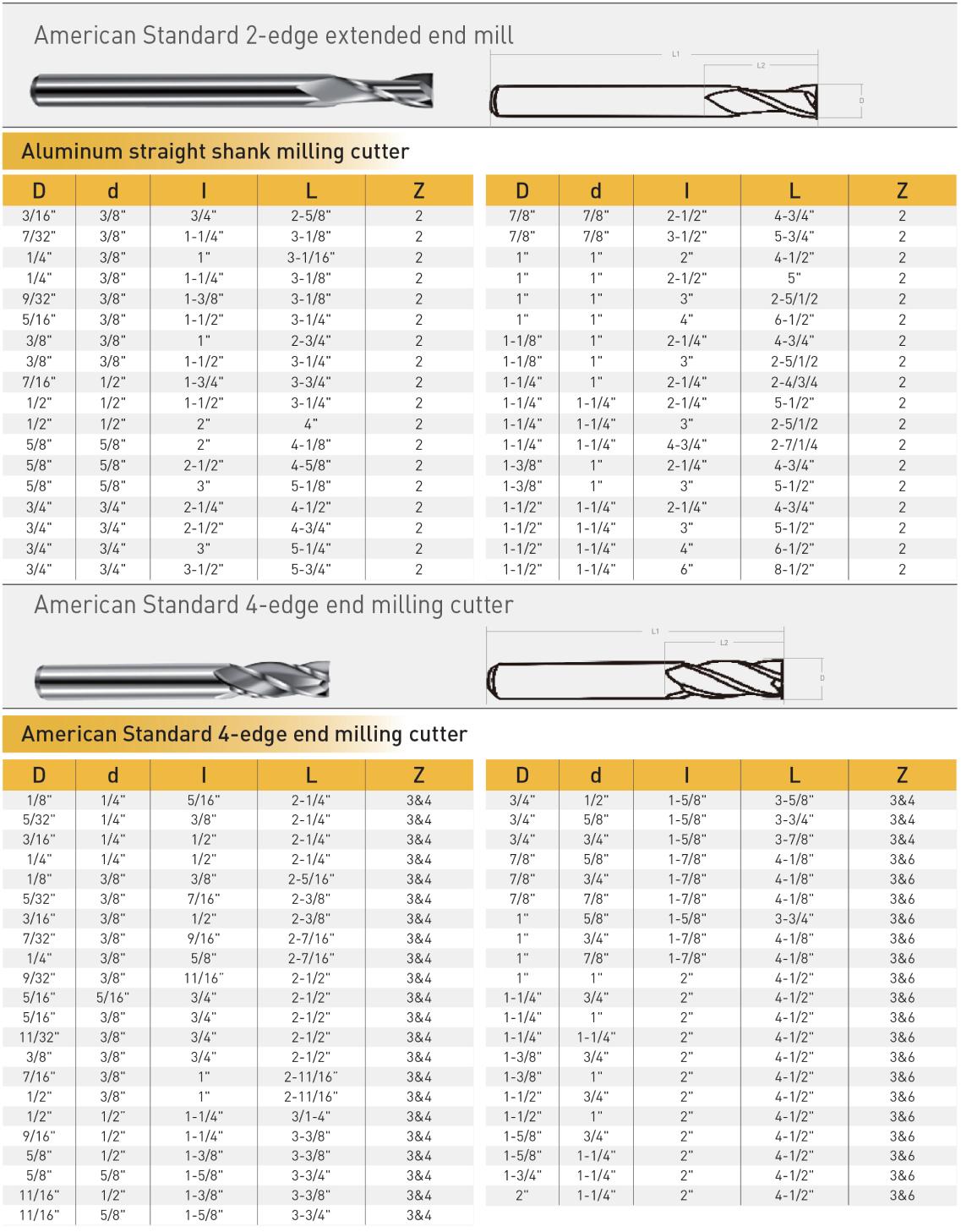

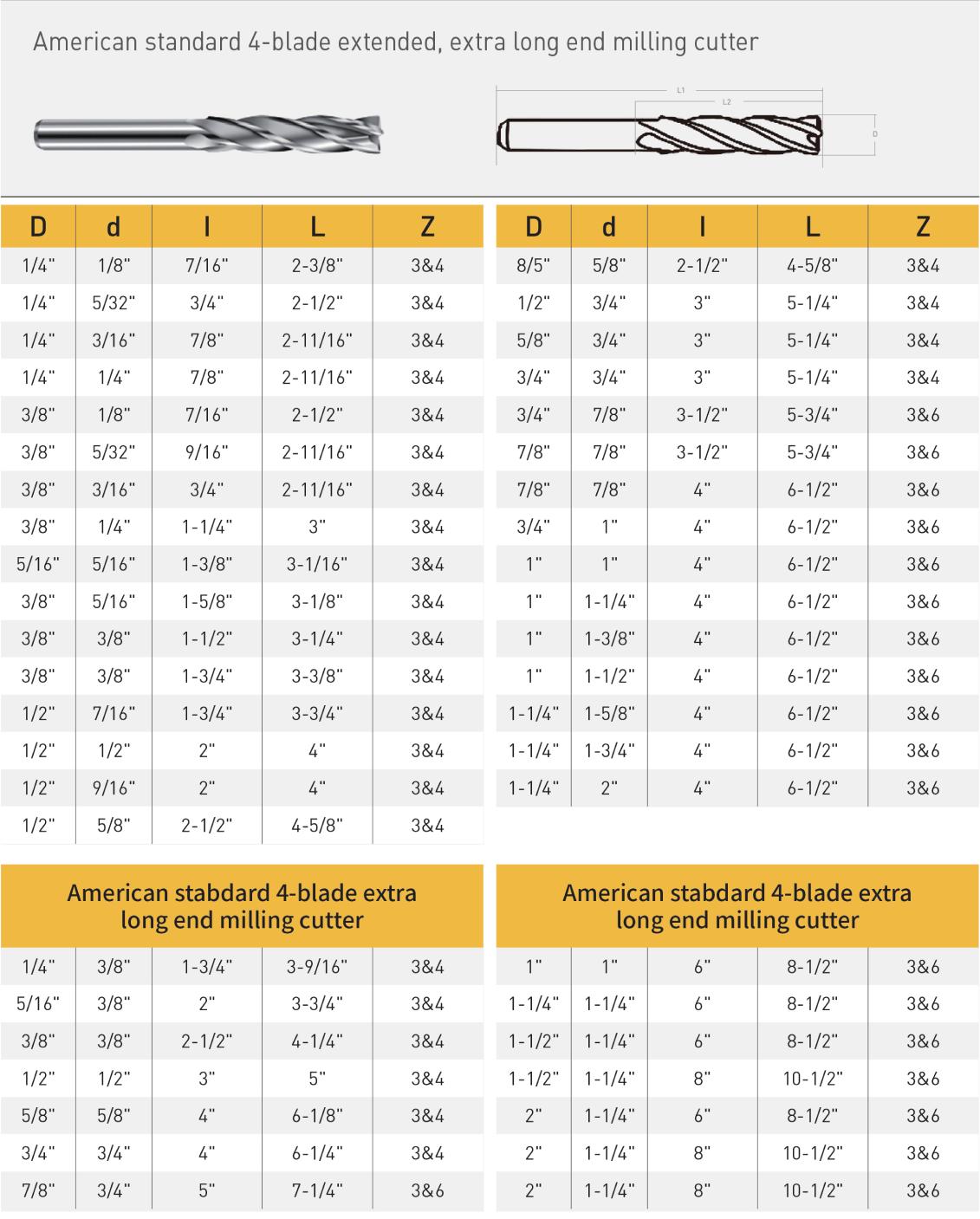

Product Size

Product Description

As a result of the cutting process, milling cutters generate a large amount of heat, especially at high cutting speeds, which leads to a sharp increase in temperature. High temperatures will cause the tool to lose its hardness, resulting in a decrease in cutting efficiency if its heat resistance is not good. The hardness of our milling cutter materials remains high at high temperatures, allowing them to continue cutting. This property is also known as thermohardness or red hardness. In order to avoid tool failure due to overheating, the cutting tool must be heat resistant in order to maintain stable cutting performance under high temperatures.

Erurocut milling cutters also possess high strength and excellent toughness. During the cutting process, the cutting tool must withstand a large amount of impact force, so it must be strong, otherwise it will easily break and be damaged. Milling cutters will also be impacted and vibrated during the cutting process, so they must also be tough to prevent chipping and chipping problems. Under complex and changing cutting conditions, a cutting tool can only maintain stable and reliable cutting capabilities if it has these properties.

To ensure that the milling cutter is in correct contact with the workpiece and at the right angle when it is installed and adjusted, strict operating steps must be followed. By doing so, not only will processing efficiency be improved, but improper adjustment also won't result in damage to workpieces or equipment failure.